Wireless Digital Input Sensors for Industrial Monitoring

Monitoring digital signals from meters, counters, or switches can be complex when devices are spread across large industrial sites. Daviteq’s wireless digital input sensors simplify deployment by capturing ON/OFF status, pulses, and counters remotely — reducing cabling costs, improving data reliability, and enabling real-time process visibility.

DIGITAL INPUT

Struggling with complex signal monitoring?

Many facilities still rely on manual checks or wired systems that are:

-

Prone to signal loss or noise interference

-

Expensive to install and maintain

-

Difficult to monitor across multiple devices or locations

Wireless digital input sensing simplifies signal collection from meters, counters, and switches — improving efficiency, reducing downtime, and enabling predictive maintenance.

Why Choose Daviteq?

Typical Applications

Use-cases

undefined

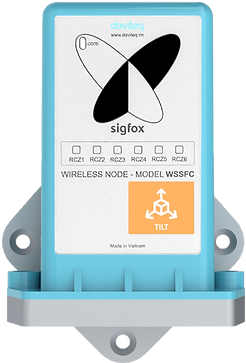

Explore Daviteq Products

undefined

Resources

Frequently Asked Questions

What signals can Daviteq digital input sensors capture?

They detect ON/OFF status, dry contact, and pulse signals from various devices such as flow meters, counters, and switches. This flexibility allows one sensor type to serve multiple applications in utilities, industry, and building automation.

How reliable are wireless digital input sensors compared to wired systems?

Daviteq sensors are engineered with robust wireless protocols and industrial-grade housings. They provide stable performance in harsh conditions, while eliminating the risks of cable damage, electrical noise, or costly rewiring.

How long do the sensors operate before battery replacement?

Thanks to ultra-low-power technology, our sensors can run for up to 10 years on standard batteries. This makes them ideal for remote or hard-to-access locations where frequent maintenance is impractical.

Can digital input data integrate into existing SCADA or IoT platforms?

Yes, all sensors support LoRaWAN, Sigfox, NB-IoT, and LTE-M, as well as Modbus through gateway integration. This ensures seamless connection with both traditional industrial systems and modern cloud-based IoT platforms.