Wireless Gas Sensors for Industrial Monitoring

Detecting and monitoring gas leaks is critical for workplace safety and regulatory compliance. Daviteq’s wireless gas sensors are rugged, intrinsically safe, and engineered for long-term accuracy in harsh industrial environments — helping you identify hazardous gases before they become threats.

GAS

Struggling with unreliable gas detection?

Many industries still depend on manual inspections or outdated wired systems that are:

-

Slow to detect hazardous gas leaks

-

Expensive to install and maintain

-

Unreliable in harsh or remote areas

Wireless gas sensing helps ensure safety, compliance, and efficiency — providing continuous, real-time detection of leaks and hazardous gases across your entire operation.

Why Choose Daviteq?

Typical Applications

Use-cases

undefined

Explore Daviteq Products

undefined

Resources

Frequently Asked Questions

What gases can Daviteq sensors detect?

Daviteq sensors can be configured to detect a wide range of gases, including methane (CH₄), carbon monoxide (CO), carbon dioxide (CO₂), hydrogen sulfide (H₂S), ammonia (NH₃), and other toxic or flammable gases. Each sensor is designed with specific detection principles to ensure sensitivity and selectivity, giving accurate readings even at low concentrations. This makes them suitable for diverse industries, from oil refineries to food processing plants.

Are these sensors suitable for explosive or hazardous environments?

Yes, Daviteq provides ATEX and IECEx-certified gas sensors specifically designed for hazardous areas where explosive gases may be present. These models feature intrinsically safe designs and rugged housings to withstand harsh operating conditions. By meeting international safety standards, they allow customers in oil & gas, mining, and chemical processing to confidently deploy monitoring systems without compromising worker safety or regulatory compliance.

How long do gas sensors last before calibration or replacement?

Our wireless gas sensors are designed for long-term stability, with operating lifespans of up to 10 years depending on the target gas and application environment. Calibration requirements vary: some gases like CO₂ may need less frequent adjustment, while others, such as H₂S, benefit from regular checks. To simplify maintenance, Daviteq supports remote diagnostics and provides clear guidance on calibration intervals, helping customers balance reliability with cost efficiency.

Do Daviteq sensors integrate with SCADA and IoT systems?

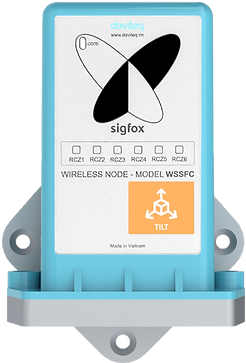

Yes, integration is a key feature of our product line. Daviteq gas sensors support multiple protocols such as LoRaWAN, Sigfox, NB-IoT, LTE-M, and Modbus, making them compatible with both legacy SCADA/DCS systems and modern IoT platforms. Data from the sensors can be visualised on dashboards, stored in the cloud, or linked directly into customer ERP/MES systems, giving decision-makers a single source of truth for gas safety and compliance.