Wireless Relay and Actuators for IoT System Controlling

Monitor and control relay status from Daviteq wireless sensors - reliable remote switching for IoT and industrial applications.

RELAY & ACTUATORS

Struggling with unreliable remote switching?

Many factories still depend on manual control or wired relay systems that are:

-

Slow to react and prone to human error

-

Costly to install, rewire, and maintain

-

Hard to scale across multiple machines and locations

Wireless relay control delivers reliable, real-time switching for industrial equipment — helping automate pumps, valves, lighting, alarms, and actuators without downtime or messy cabling.

Why Choose Daviteq?

Typical Applications

Use-cases

undefined

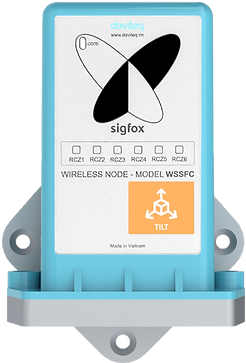

Explore Daviteq Products

undefined

Resources

Frequently Asked Questions

What can wireless relay control be used for?

Daviteq wireless relay devices enable remote switching of industrial equipment, including pumps, valves, lighting systems, alarms, and actuators. They support automation tasks and allow operators to control multiple machines from a single dashboard, reducing labour and minimising response time.

Can Daviteq relay devices be installed in harsh industrial environments?

Yes. All relay modules are designed with rugged enclosures and industrial-grade protection to withstand dust, moisture, and temperature extremes. They are proven in heavy-duty applications such as water treatment, manufacturing, energy, and remote facilities, where reliable switching is critical.

How long do wireless relay devices operate before battery replacement?

Thanks to ultra-low-power design, Daviteq wireless relays can operate for years on standard batteries. Actual lifespan depends on switching frequency and environmental conditions, but most users experience long, maintenance-free operation that reduces the total cost of ownership.

Do these devices support integration with existing control systems?

Absolutely. Daviteq wireless relay devices can interface with IoT platforms, SCADA systems, PLCs, and cloud-based automation tools. This enables seamless deployment, remote monitoring, automated scheduling, and improved operational efficiency across industrial sites.