Wireless Vibration Sensors for Industrial Monitoring

Machine failure often starts with subtle changes in vibration patterns. Daviteq’s wireless vibration sensors detect imbalance, misalignment, or bearing wear early — enabling predictive maintenance and preventing costly downtime in rotating equipment.

VIBRATION

Struggling with unexpected machine breakdowns?

Many factories still rely on manual inspections or wired vibration systems that are:

-

Too slow to detect early signs of imbalance or misalignment

-

Expensive to install and maintain

-

Difficult to monitor across multiple machines

Wireless vibration sensing delivers continuous, in-time data on machine health — helping detect bearing wear, imbalance, and misalignment before costly downtime occurs.

Why Choose Daviteq?

Typical Applications

Use-cases

undefined

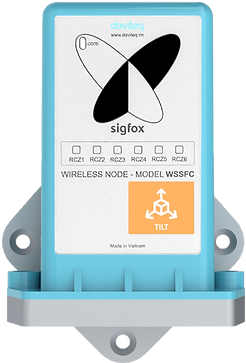

Explore Daviteq Products

undefined

Resources

Frequently Asked Questions

What can vibration sensors detect in machinery?

Daviteq vibration sensors identify early signs of imbalance, misalignment, looseness, and bearing or gear defects that are often invisible during routine inspections. By detecting these issues at an early stage, the system allows maintenance teams to act before they escalate into major failures, saving both time and repair costs.

Can Daviteq vibration sensors be used in harsh industrial environments?

Yes, all sensors are built with rugged enclosures, IP67 protection, and optional explosion-proof certification to withstand dust, moisture, and extreme temperatures. They are proven in heavy industries such as mining, oil & gas, and manufacturing, where conditions are demanding, but reliability is non-negotiable.

How long do vibration sensors typically last before a battery replacement?

Thanks to ultra-low-power design, Daviteq wireless vibration sensors can operate for up to 10 years on standard batteries. Actual lifespan depends on reporting interval and environment, but most users experience long maintenance-free service that reduces the total cost of ownership.

Do these sensors support predictive maintenance programs?

Absolutely. Vibration data is continuously transmitted and analysed to identify abnormal patterns indicative of equipment degradation. This enables predictive maintenance strategies, helping companies reduce unplanned downtime, extend machine lifetime, and improve overall plant efficiency.