What is LoRaWAN Network Server?

- Nguyen Vinh Loc

- Jun 27, 2025

- 19 min read

Updated: Aug 15, 2025

As Industrial IoT (IIoT) adoption accelerates, modern smart factories are deploying thousands of wireless sensors to monitor everything from machine vibration to environmental conditions. These sensors must communicate reliably over long distances, operate on low power, and scale effortlessly as operations expand.

Enter LoRaWAN - a leading Low Power Wide Area Network (LPWAN) technology designed to meet exactly these challenges. It offers long-range connectivity, exceptional battery efficiency, and the ability to support thousands of devices in a single network. That’s why LoRaWAN has become a go-to choice for IIoT applications in manufacturing, energy, agriculture, and beyond.

According to industry analyst firm Omdia, LoRaWAN is expected to help drive LPWAN connections beyond 3.5 billion by 2030, reinforcing its leadership in the field. As of June 2024, over 350 million end nodes and 6.9 million gateways with LoRa ICs have been deployed globally. LoRa Alliance members are self-reporting strong growth:

Actility reports 4 million connected devices with over 50% CAGR.

The Things Industries supports 2.7 million devices with 50% YoY growth.

ZENNER has deployed more than 9 million devices worldwide.

Major global brands such as Starbucks, Volvo, Chevron, and Logitech are now leveraging LoRaWAN in enterprise and private deployments—clear evidence of the technology’s maturity and scalability.

At the heart of every successful LoRaWAN deployment lies the LoRaWAN Network Server—the central brain of the network. This critical component manages device onboarding, traffic routing, MAC command handling, and network optimization. Without it, even the most advanced wireless infrastructure would be unable to operate reliably or securely.

In this article, we’ll break down what a LoRaWAN Network Server is, how it works, and why it's a foundational element for any scalable smart factory infrastructure.

Quick Recap: LoRa vs. LoRaWAN Architecture

Before diving deeper into the Network Server, it’s important to understand the distinction between LoRa and LoRaWAN, as they serve very different purposes within the wireless ecosystem.

LoRa is the physical layer—a proprietary modulation technology based on chirp spread spectrum (CSS). It enables long-range wireless communication with ultra-low power consumption, making it ideal for battery-operated sensors in industrial environments.

LoRaWAN, on the other hand, operates at the network layer (MAC layer). It defines the communication protocol and system architecture for how devices connect, transmit data, and are managed across the network. This includes aspects like message encryption, duty cycle management, and adaptive data rate (ADR) control.

A typical LoRaWAN network architecture includes four core components:

Sensor Node (End Device) – Battery-powered devices equipped with sensors that collect and transmit data.

Gateway – Acts as a bridge, forwarding data between sensor nodes and the network server using LoRa and IP connections.

Network Server – The central brain of the system, managing packet deduplication, device authentication, MAC command handling, and overall traffic routing.

Application Server – The endpoint that receives and processes decoded sensor data, typically feeding into dashboards, alerts, or analytics platforms.

Among these, the LoRaWAN Network Server plays a critical role in orchestrating all data flows between gateways and applications. It ensures secure, reliable, and efficient communication—especially when dealing with thousands of devices spread across a smart factory.

What is LoRaWAN Network Server?

In a typical LoRaWAN network architecture, the Network Server is a central software component responsible for managing communication between end devices, gateways, and application servers. While it often operates behind the scenes, it plays a crucial role in ensuring the entire system remains secure, efficient, and scalable.

A technical overview of LoRa and LoRaWAN “The intelligence and complexity is pushed to the network server, which manages the network and will filter redundant received packets, perform security checks, schedule acknowledgments through the optimal gateway, and perform adaptive data rate, etc.” — LoRa Alliance

Whenever a sensor sends out a data packet, that message can be picked up by multiple gateways. These gateways forward the data to the Network Server over IP. From there, the Network Server handles a series of intelligent processing steps:

Removes duplicate packets received from different gateways.

Routes payloads to the appropriate application server.

Manages MAC-layer communication, such as acknowledgments, link checks, and adaptive data rate (ADR).

Handles security checks, ensuring that only authenticated messages are processed.

Activates and manages devices, using methods like Over-The-Air Activation (OTAA) or Activation by Personalization (ABP).

In many ways, the Network Server functions as the "brain" of the LoRaWAN system. It enforces the rules of communication, coordinates traffic, and ensures reliable delivery of data.

Think of it as the traffic controller of your wireless infrastructure—directing thousands of data streams in time. Or like a conductor in a smart orchestra, keeping every instrument (sensor and gateway) in sync to produce accurate, efficient, and secure operations.

Core Functions of Network Server

The LoRaWAN Network Server is more than just a message router—it’s the control hub that enables a LoRaWAN network to operate securely, efficiently, and intelligently. Below are its five core functions that make it indispensable in industrial deployments:

Device Activation & Management

Before a device can send data over a LoRaWAN network, it must first be authenticated and securely connected. This process is called device activation, and it’s one of the key jobs of the LoRaWAN Network Server.

There are two main activation methods: Over-The-Air Activation (OTAA) and Activation By Personalization (ABP). Both methods establish secure communication using cryptographic session keys—but they do it in very different ways.

Over-The-Air Activation (OTAA)

OTAA is the most secure and scalable activation method—and the preferred choice for industrial environments.

When a new device powers up, it sends a Join Request to the Network Server. This request includes its unique device ID and a random number to prevent replay attacks. The Network Server passes this request to the Join Server, which verifies the device and responds with a Join Accept message. That message contains:

A network address (DevAddr)

Two session keys: NwkSKey for managing network-level traffic and AppSKey for encrypting sensor data

These keys are generated dynamically, which means they’re unique to each session. This allows for end-to-end encryption between the device and the application server—critical for protecting sensitive industrial data. In a smart factory with hundreds (or thousands) of wireless sensors, OTAA makes it easy to onboard new devices, rotate old ones, and maintain strong security without touching each node manually.

Activation By Personalization (ABP)

ABP skips the join procedure. Devices are manually pre-configured with their address and session keys before deployment.

This allows devices to transmit data immediately, which sounds convenient—but it comes at a cost:

Keys are static and harder to rotate

Devices can’t easily adapt to network-side changes

Manual provisioning doesn’t scale well in large deployments

ABP may be acceptable for small test networks or fixed, low-risk environments—but for modern IIoT systems, it’s usually a temporary solution at best.

OTAA offers stronger security, smoother device management, and better long-term flexibility. And behind the scenes, the Network Server orchestrates the entire activation process—validating devices, securing communication, and setting the foundation for a reliable LoRaWAN deployment.

Data Deduplication

LoRaWAN networks are designed to support redundancy by architecture. When a device sends an uplink message, it can be received by multiple gateways simultaneously—especially in dense industrial environments with overlapping coverage zones. This behavior is intentional: it increases fault tolerance, enables better signal path selection, and strengthens network resilience. However, it also creates a side effect—duplicate packets—which must be handled efficiently.

Each gateway forwards the packets it receives to the Network Server via IP backhaul. These packets may contain identical payloads, but they arrive at slightly different times and with different signal quality metrics (RSSI, SNR).

The Network Server inspects each packet’s metadata, including:

DevAddr (device address)

FCntUp (frame counter for uplinks)

MIC (message integrity code)

If the server detects that multiple packets belong to the same transmission event, it retains only one instance—typically the version with the highest link quality. The remaining duplicates are silently dropped before reaching the Application Server.

Without deduplication, a single uplink message could inadvertently trigger multiple alarms or processing events on the application side, since each copy would be treated as a separate input. It could also inflate storage and analytics pipelines with redundant data, leading to inefficient database usage and skewed results. Moreover, in scenarios where a downlink is required, the system would struggle to identify the optimal return path, as it wouldn’t know which gateway has the best link to the device.

Deduplication is not just an optimization—it’s a foundational requirement for reliable LoRaWAN operation in environments with high gateway density. The Network Server executes this function automatically, enabling clean, efficient, and scalable data delivery across the entire IIoT stack.

Adaptive Data Rate (ADR)

In LoRaWAN, optimizing communication parameters is critical for both network efficiency and device longevity. That’s where Adaptive Data Rate (ADR) comes in—a mechanism coordinated by the Network Server to dynamically adjust how devices transmit. Unlike fixed-rate systems, ADR enables LoRaWAN devices to modify their spreading factor (SF), transmit power, and data rate based on in-time link conditions.

When ADR is enabled on a device, the Network Server continuously analyzes the quality of recent uplinks—specifically signal-to-noise ratio (SNR), received signal strength (RSSI), and transmission success.

Using this data, the server sends MAC commands (e.g., LinkADRReq) instructing the device to:

Lower its spreading factor when the link is strong, enabling shorter airtime and higher throughput

Increase the spreading factor or transmit power when the signal degrades, improving reliability

These adjustments are gradual and based on long-term link statistics, ensuring stability rather than frequent oscillations.

In industrial environments where thousands of devices operate concurrently, ADR brings three critical advantages:

Extended battery lifeDevices spend less time on-air, reducing energy consumption—especially important for battery-powered sensors in hard-to-reach areas.

Reduced network congestionBy minimizing airtime, ADR increases overall channel availability and reduces packet collisions across the network.

Improved communication reliabilityAdaptive tuning helps maintain strong connections even as environmental conditions (like interference or physical obstructions) change over time.

ADR is not just a power-saving feature—it’s a key strategy for ensuring scalable and resilient communication in high-density LoRaWAN deployments. The Network Server orchestrates this process intelligently, striking the balance between energy efficiency and data reliability.

MAC Command Handling

Beyond transporting application data, LoRaWAN also allows for bi-directional control between devices and the network. This control happens through MAC commands (Medium Access Control), which are managed and issued by the Network Server. These commands are embedded in uplink or downlink frames and enable the server to remotely configure, optimize, and govern device behavior at the radio protocol level.

The Network Server monitors device performance, link conditions, and overall network health. When needed, it sends specific MAC commands to individual devices to adjust their configuration. Common examples include:

LinkADRReq – Instructs the device to modify spreading factor, data rate, and transmission power

DutyCycleReq – Enforces regional duty cycle limits to avoid radio spectrum congestion

RXParamSetupReq – Configures the timing and frequency of receive windows for downlink messages

DevStatusReq – Queries the device for battery level and link margin

Devices respond with acknowledgment messages or status updates, creating a lightweight feedback loop that allows the Network Server to maintain control without disrupting application data. In smart factories, where device behavior may need to adapt to environmental changes, production schedules, or interference patterns, MAC command handling provides essential flexibility. For example:

Devices deep inside metal enclosures may need higher transmit power

Sensors in low-noise zones can be assigned lower spreading factors to improve capacity

Maintenance routines can temporarily limit data transmission using duty cycle commands

This level of remote configuration enables fine-grained, centralized control of thousands of devices—without manual reprogramming or physical access.

MAC command handling is how the Network Server enforces network policy, adapts to changing conditions, and fine-tunes device performance in time. It’s a lightweight, low-overhead mechanism that enables LoRaWAN networks to operate efficiently, compliantly, and at scale.

Security Management

Security is fundamental to any wireless communication system—especially in industrial environments where data integrity and system reliability are non-negotiable. In LoRaWAN, end-to-end security is built into the protocol, and the Network Server plays a central role in enforcing and maintaining it.

LoRaWAN uses two separate encryption layers to secure communication:

Network-level encryption, handled via the NwkSKey, ensures message integrity and validates that messages are coming from trusted devices.

Application-level encryption, using the AppSKey, protects the actual payload data. This key is only visible to the application server, keeping the Network Server blind to user data content.

This dual-key architecture ensures that even if the Network Server or gateways are compromised, sensor data remains confidential until it reaches its intended destination.

During OTAA (Over-The-Air Activation), the Network Server collaborates with the Join Server to securely generate and exchange session keys unique to each device. These keys are not static; they can be refreshed with every join cycle, minimizing the attack surface over time.

In ABP (Activation By Personalization), the Network Server works with pre-configured static keys, which are less secure and more vulnerable to replay or cloning attacks—another reason why OTAA is strongly recommended in production environments. The Network Server continuously validates:

Frame counters, to prevent message replay

Message Integrity Codes (MICs), to ensure authenticity

Device identity and session state, to verify that each message comes from a valid, active node

Any anomaly—such as a counter mismatch or invalid MIC—is flagged, and the message is discarded without reaching the application layer.

The Network Server is not just a router—it’s a gatekeeper for trust. By managing key distribution, enforcing encryption protocols, and validating device communication, it ensures that LoRaWAN networks remain secure, reliable, and resilient against tampering or data leaks—even at scale.

LoRaWAN Network Server Deployment Architecture

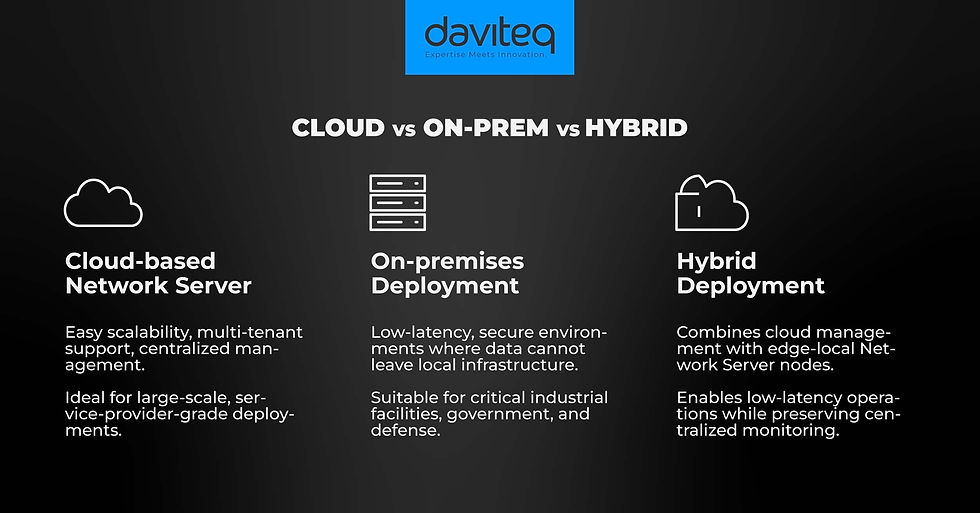

How and where you deploy a LoRaWAN Network Server can significantly affect the performance, scalability, and security of your IIoT system. LoRaWAN supports flexible deployment models to match a wide range of industrial use cases—from globally distributed operations to air-gapped manufacturing lines. Below are the three most common architectures, along with the typical data flow across the network stack.

Cloud-based Network Server

Cloud-based Network Servers run as fully managed services hosted on public or private cloud infrastructure. Providers like The Things Stack Cloud, Loriot, or AWS IoT Core for LoRaWAN offer scalable platforms that handle all core functions—from device management to MAC layer control—without requiring on-site hardware.

This model offers several benefits:

Elastic scalability: Easily support thousands or millions of devices across geographies, with automated load balancing and failover.

Multi-tenancy: Separate environments for different business units or clients can be managed within the same instance.

Centralized updates: Security patches, firmware upgrades, and network policies are deployed globally without physical intervention.

Cloud-based deployments are ideal for manufacturers with distributed operations or OEMs offering LoRaWAN-as-a-service to downstream clients. They significantly reduce infrastructure burden while providing high availability and consistent uptime—assuming internet connectivity is reliable.

However, latency may be higher for time-sensitive applications, and data sovereignty or compliance requirements could pose limitations in regulated industries.

On-premises Deployment

In an on-prem deployment, the Network Server runs on local infrastructure—either as a physical appliance or a virtual instance within a factory network (LAN or edge cloud). This setup keeps all LoRaWAN operations entirely within the facility perimeter.

Key advantages include:

Low latency, which is critical for in-time feedback loops (e.g., vibration alerts triggering shutdown protocols)

Data sovereignty, where sensor data never leaves the site—crucial for GDPR, HIPAA, or defense-grade compliance

Air-gapped resilience, allowing the network to operate even if internet connectivity is lost or restricted

This model is commonly adopted by industrial manufacturers, government agencies, utilities, and critical infrastructure providers, where control and security are paramount.

The trade-off? It requires local IT resources for setup, maintenance, and scaling. Additionally, remote access and central monitoring become more complex unless bridged through secure VPNs or APIs.

Hybrid Deployment Model

Hybrid architectures strike a balance between control and convenience. In this model, LoRaWAN Network Servers are distributed across edge sites (factories, facilities, campuses), while a centralized cloud layer handles policy orchestration, analytics, firmware delivery, and integration with enterprise systems (ERP, SCADA, etc.).

This architecture allows:

Autonomous site operation: Each local network server can continue processing packets, executing ADR, and issuing MAC commands independently—even during cloud outages.

Global visibility and control: The cloud layer maintains a central view of the entire fleet, enabling cross-site benchmarking, alerting, and configuration management.

Hybrid deployments are increasingly popular with multi-site manufacturers or industrial solution providers who require both local resiliency and enterprise-level visibility. It supports differentiated SLA tiers per site and offers flexibility for progressive digital transformation.

Challenges may include higher deployment complexity and the need for robust synchronization logic between cloud and edge.

Full Architecture Data Flow:

Regardless of the deployment model, the logical data path in a LoRaWAN system remains consistent:

Sensor Node (End Device): Transmits encrypted LoRa packets on predefined frequencies using Class A/B/C profiles.

Gateway: Receives packets via RF and forwards them over IP to the Network Server. Gateways are stateless and act as transparent bridges.

Network Server: Processes incoming packets (deduplication, MIC validation), manages MAC layer, performs ADR, and handles device sessions.

Application Server: Decrypts payloads (using AppSKey) and parses data into usable formats (e.g., JSON, MQTT) for business logic.

End-User Applications: Dashboards, maintenance platforms, or ERP systems that consume sensor insights for monitoring, alerting, and automation.

This modular architecture enables clean separation of concerns, allowing each component to evolve independently while maintaining interoperability and security.

How LoRaWAN Network Server Enables Smart Factory

Wireless sensors are not just accessories—they’re foundational to in-time visibility and autonomous operations. From predictive maintenance to process efficiency, thousands of LoRaWAN-connected sensors are deployed across assembly lines, warehouses, and utility zones. But enabling that level of connectivity isn’t just about deploying devices—it’s about managing them intelligently, securely, and at scale.

This is where the LoRaWAN Network Server becomes mission-critical. Acting as the orchestration layer behind the scenes, it ensures that every packet is authenticated, deduplicated, optimized, and routed properly. Whether you’re managing a dozen gateways or thousands of end devices, the Network Server is the piece that makes large-scale, low-power wireless infrastructure actually work. Let’s explore how it empowers smart factory operations—from data reliability to enterprise integration.

High-Density Sensor Management

In modern smart factories, deploying thousands of wireless sensors isn’t the challenge—it’s managing them intelligently at scale. That’s where the LoRaWAN Network Server proves essential.

As sensors come online, the Network Server handles secure activation using OTAA, dynamically generating and assigning session keys through coordination with the Join Server. For large fleets, this process can be fully automated via provisioning APIs, drastically reducing setup time and human error.

Once active, each device session is tracked in time—maintaining counters, MAC state, and signal quality. This allows the Network Server to apply configuration updates, respond to status queries, and manage traffic without overloading the system, even with tens of thousands of devices running concurrently.

In high-density environments with overlapping gateway coverage, coordination becomes critical. The Network Server evaluates signal conditions and determines the most reliable gateway for downlink delivery. This ensures communication stays efficient, even as devices move between zones or operate in harsh industrial settings.

Ultimately, the Network Server abstracts the complexity of scale, enabling factories to focus on insights and outcomes—rather than infrastructure logistics.

Clean data through deduplication

In high-coverage smart factory environments, it’s common for the same uplink message to be received by multiple gateways at once. While this redundancy improves reliability, it can also result in repeated packets flooding the backend if not properly handled.

The LoRaWAN Network Server plays a critical role in resolving this. Upon receiving identical messages from different gateways, it performs intelligent deduplication—comparing timestamps, frame counters, and signal quality to retain only the best copy. This ensures that the application layer receives a single, clean, and validated data stream, free from duplication noise.

By filtering at the network layer, the server prevents unnecessary processing downstream, protects analytics from skewed results, and helps maintain predictable system behavior—even as the number of gateways and sensors continues to grow.

This kind of network intelligence is essential in industrial environments, where clean datasets are foundational to reliable automation, in-time alerting, and machine learning–driven insights.

Battery optimization with ADR

In industrial IoT deployments, especially those covering wide factory floors or hard-to-access infrastructure, battery life isn’t just a technical detail—it’s an operational constraint. Replacing or recharging thousands of devices disrupts workflows and adds ongoing labor costs. That’s why Adaptive Data Rate (ADR), managed by the Network Server, plays such a pivotal role.

ADR allows the Network Server to continuously analyze how well each sensor is communicating— monitoring factors like signal-to-noise ratio and packet success rates. When conditions are favorable, the server can instruct a device to lower its spreading factor or reduce transmit power, effectively shortening airtime and minimizing energy use. Conversely, in noisy or obstructed environments, it can reconfigure the sensor to ensure the message still gets through, even if it costs slightly more battery.

This in-time balancing act helps extend the life of batteries by months, sometimes years—without compromising data reliability. For factories running critical processes 24/7, that means fewer service interruptions, less technician time in hazardous zones, and a more predictable maintenance schedule.

In short, ADR isn't just a network feature—it’s a strategy for making high-density wireless systems both sustainable and scalable.

Remote Network Control

As factories scale their operations across multiple production lines—or even across multiple geographic sites—network visibility and control become critical. The LoRaWAN Network Server acts as the central command layer, giving operators a unified interface to monitor and manage every connected sensor in the system, no matter where it's deployed.

Through the Network Server, factory teams can view device status, track signal performance, diagnose communication issues, and apply configuration changes remotely—without ever needing physical access to the sensor or gateway. This level of control allows teams to adapt to changing conditions quickly, whether it’s optimizing data rates to reduce congestion, isolating a malfunctioning sensor, or issuing firmware updates over the air.

In highly automated environments, this centralized control translates into faster response times, improved uptime, and reduced dependency on on-site IT or maintenance resources. Whether troubleshooting a node in a sub-basement or adjusting reporting intervals on a roof-mounted sensor, the Network Server ensures that factory operators stay in full control of their wireless infrastructure from anywhere.

Predictive Maintenance Integration

In modern manufacturing, unplanned downtime is one of the most expensive disruptions—and predictive maintenance has become a frontline defense. LoRaWAN networks, powered by wireless vibration, temperature, or pressure sensors, continuously monitor equipment health and feed critical metrics upstream. But it’s the Network Server that ensures this data flows reliably and securely into enterprise systems where in-time decisions are made.

By acting as the data conduit between field devices and backend platforms like MES, SCADA, or ERP, the Network Server guarantees low-latency, high-integrity delivery of sensor readings. It handles deduplication, message validation, and secure routing—so only clean, trusted data reaches business logic layers.

This seamless integration enables factories to build automated workflows that detect anomalies early, generate maintenance tickets, or even halt processes before damage occurs. When combined with machine learning algorithms, the result is a smarter factory—one that not only knows when something is wrong but can act before failure happens.

In this context, the Network Server isn’t just part of the infrastructure—it’s a catalyst for transforming raw sensor signals into actionable insights that save time, money, and machinery.

Learn More:

Performance Considerations & Scalability

As LoRaWAN adoption scales in industrial settings, the Network Server must do more than route packets—it must perform consistently under pressure. From millisecond response times to global roaming support, its architecture plays a decisive role in sustaining performance and future growth.

In time-sensitive environments like machine control or safety systems, latency matters. The Network Server must be optimized to process uplinks and schedule downlinks with minimal delay. This often requires edge-local deployment or hybrid models that push decision logic closer to the factory floor—especially where sub-second responsiveness is critical.

To support 24/7 operations, the server infrastructure must be fault-tolerant. High-availability clustering, automatic failover, and horizontal scaling are essential to prevent data loss or system outage. LoRaWAN doesn’t inherently guarantee delivery, so the Network Server must be engineered with its own redundancy logic and data durability layers.

In multi-site factories or global deployments, devices may move across gateway zones. The Network Server must support seamless roaming across regions, maintaining session continuity, re-establishing link metrics, and enforcing security policies without interrupting application-level workflows.

Finally, performance must align with compliance. The server must enforce region-specific frequency plans, channel configurations, and duty cycle limitations defined by local regulators (e.g., ETSI in Europe, FCC in the U.S.). This includes adhering to adaptive channel masks and ensuring downlink fairness in congested ISM bands.

In short, a production-grade LoRaWAN Network Server is more than protocol logic—it’s a foundation for resilient, compliant, and scalable IIoT operations.

Network Server Selection Criteria

Choosing the right LoRaWAN Network Server is a strategic decision—especially for industrial deployments where performance, interoperability, and security cannot be compromised. Beyond basic packet routing, the ideal platform must provide a foundation that is scalable, standards-compliant, and ready for enterprise integration.

At the core, scalability is non-negotiable. A production-grade server must handle thousands of concurrent devices, process millions of packets per day, and maintain performance even under burst conditions. Whether deployed on-premises or in the cloud, horizontal scaling and multi-gateway coordination must be seamless.

Standards compliance is equally essential. A conformant Network Server ensures full interoperability across LoRa Alliance–certified devices, reducing vendor lock-in and future-proofing your infrastructure. It also guarantees compatibility with advanced features like firmware over-the-air (FOTA), Class B/C device support, and roaming.

Security is not just about encryption—it’s about key lifecycle management, Join Server coordination, and enforcing LoRaWAN’s dual-layer cryptography at scale. A strong server should support hardware-based key storage (e.g., HSMs), secure onboarding, and centralized key rotation to meet the needs of regulated industries.

Integration is where a Network Server becomes truly valuable. Support for open APIs—such as MQTT, HTTPS, and RESTful endpoints—enables clean handoffs to industrial systems like MES, SCADA, or ERP. This allows in-time data streams to directly power dashboards, alarms, and automated workflows.

For service providers and large enterprises, multi-tenant management is critical. The ability to partition resources into segregated domains—each with its own users, devices, and policies—enables scalable, secure deployment across business units or external clients.

Finally, the surrounding ecosystem matters. A strong vendor offers more than just software—they provide documentation, developer tools, responsive support, and a visible roadmap. An active community ensures that you're not solving problems alone, while a mature release cycle keeps your deployment aligned with evolving LoRaWAN specifications.

Future Trends in LoRaWAN Network Server Evolution

As LoRaWAN continues to expand across industrial sectors, the role of the Network Server is evolving beyond traditional routing and device management. Emerging technologies are reshaping how network intelligence is distributed, optimized, and secured—opening new possibilities for more autonomous, resilient, and efficient wireless infrastructures.

One major trend is the rise of decentralized architectures, inspired by blockchain-based models such as Helium. These systems distribute network ownership and operation across thousands of independent participants, enabling ultra-scalable deployments without relying on a single operator. While not yet mainstream in industrial settings, such decentralized network servers introduce intriguing possibilities for shared infrastructure in smart cities and public utilities.

Another area gaining momentum is AI/ML-optimized Adaptive Data Rate (ADR). Instead of relying solely on static link metrics like RSSI or SNR, next-generation Network Servers are beginning to integrate machine learning algorithms that consider temporal patterns, environmental conditions, and traffic history to adjust data rates dynamically. This can lead to better energy efficiency and more stable links—especially in environments with fluctuating interference or mobility.

At the infrastructure level, the shift toward edge-embedded Network Servers is pushing intelligence closer to where data originates. By deploying lightweight server components alongside industrial gateways or inside private cloud zones, factories can reduce latency, preserve local autonomy, and maintain network continuity even when disconnected from central services. This model aligns with the growing demand for in-time analytics and closed-loop control at the edge.

Together, these trends point toward a future where LoRaWAN networks are not only smarter and faster—but also more adaptive, distributed, and autonomous.

In a smart factory, every sensor reading matters—and ensuring that data reaches the right system, at the right time, under the right conditions, is what sets apart experimental pilots from enterprise-grade deployments. The LoRaWAN Network Server sits at the heart of that transformation. It’s more than a message router; it’s the brain of the wireless sensor network—coordinating activation, optimizing transmissions, enforcing security, and powering integration across industrial platforms.

As factories move toward predictive, data-driven operations, choosing the right Network Server becomes a strategic infrastructure decision. Whether you’re deploying hundreds of devices across one facility or scaling across multiple sites, the performance, architecture, and ecosystem support behind your server will determine how far—and how fast—you can go.

If you’re evaluating LoRaWAN for your smart factory initiatives, now is the time to think beyond sensors and gateways. It’s time to evaluate the intelligence layer that makes your wireless network work.

Comments