Machine Tool Monitoring Solution

Challenges Customers meet

From Daily operation

Labour is wasted on manual inspecting and reporting.

It is suspected that machines are not used effectively but unable to identify the causes.

Data for machine monitoring, collected manually, are missing, low reliable and not updated.

There is not comprehensive monitoring solution for machine (production progress, operation, OEE...).

Problems that reduce machine performance are detected and reported slowly to relevant departments.

From Other solutions

The installation costs are significantly higher when using wired solutions.

Monitoring is challenging when there is a large number of machines and equipment scattered across the area.

Maintenance and repairs are challenging and costly, especially when pinpointing the location of wiring issues.

Solution

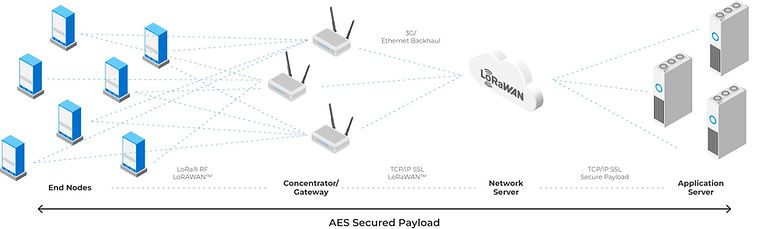

Solution Diagram

Features

Automatic

Automatically collect operation status, production output, product quality, cause of machine standby, start and end of production for each item.

Diverse Features

Visualize KPIs such as usage time, performance, OEE of machine tools for production management, equipment management and operator management

Timely alerts

Instantly send alerts, events when problems or unusual events occur.

Flexibility

Flexible investment options and easy system expansion.

Unified Management

Simple data intergration to business management software (ERP, CRM...).

Benefits

Real-time monitoring of machine production progress helps management develop appropriate production plans.

Identifies the causes of machine downtime to enable corrective measures.

Receive immediate alerts for machine issues to enable quick, timely resolution and reduce downtime.

Builds trust and reputation for the business in the 4.0 era.

Related Products

I'm a paragraph. Click here to add your own text and edit me. It's easy.