LoRaWAN Ex d Process Pressure Sensor

SKU#

WSLRWEX-PPS

Replaced by

Replaced SKU

WSLRWEX-PPS is an integrated LoRaWAN process pressure sensor with Ex d approval, suitable for installation in Zone 1, Zone 2, or safe zones. It offers various types of pressure measurements, including Gauge, Absolute, and Sealed Gauge, with a range of -1 to 1000 bar. The sensor boasts high accuracy and stability. Its ultra-low-power design and intelligent firmware enable it to operate for up to 10 years on a single battery, depending on the configuration. The WSLRWEX-PPS supports all global LoRaWAN frequency bands and can also be configured to operate in P2P-LoRa mode, allowing direct data transmission to a P2P-LoRa mode end device. This versatile sensor is ideal for monitoring pressure in applications such as oil pipelines, gas pipelines, LPG tanks, and CNG tanks.

Applications

Oil & Gas Pipeline Monitor, Process Monitoring, Safety Monitoring

Supports LoRaWAN and P2P-Lora mode

LoRaWAN Specification V1.0.3 and Peer-to-Peer mode for Direct data transmission to other device

High Accuracy & Stable

Advanced Piezo technology to deliver high accuracy and stable measurement

10-Year battery

Ultra-low power sensing technology from Daviteq with Ultra-low power wireless technology allows the sensor can last up to 10 years with a single battery C

Ex d Zones 1-2-21-22

Ex d approval for installation in Zone 1, Zone 2 or Safe Zone

.

| Sensor | Advanced Piezo technology |

| Measurement range | Select from -1∼1000 bar Gage/ Absolute/ Sealed Gage (Over pressure protection: 2 x span) |

| Accuracy & Stability | 0.2% of span, < 0.1% span/ year |

| Wetted parts & Measuring Fluids | 316SS, Any fluid which is workable with materials 316SS |

| Process Working temperature | -40∼130℃ (compensation in -10∼80℃) |

| Process connection | 1/2” NPT-male as standard, others please consult factory |

| COMMUNICATION | |

| Protocol | LoRaWAN® Class A, V1.0.3 and P2P-LoRa Mode |

| SF Factors | SF7∼SF12 |

| Antenna | External Antenna 2.0 dbi |

| RF Frequency and Power | 860∼930MHz, 14∼20dBm, configurable for zones: EU868, IN865, RU864, KR920, AS923, AS923-2, AU915, US915 |

| Data sending modes | interval time, or when status changes, or manually triggered by a magnetic key. |

| Configuration | via Downlink or offline USB cable (PC software is supplied for free) |

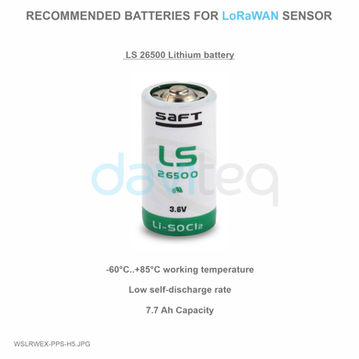

| Battery | 01 x C type LiSOCl₂ 3.6V battery, not included (recommend SAFT LS26500) |

| Housing | Cast aluminum, IP66 |

| Ex Certification | IMQ 14 ATEX 005 X, TÜV CY 18 ATEX 0206158 X and IECEx DEK 15.0048X |

| Hazardous Protection Marking | ATEX II 2G Ex db IIC T4 Gb and ATEX II 2D Ex tb IIIC T135℃ Db |

| Standards | IEC EN 60079-0, IEC EN 60079-7 and IEC EN 60079-31 |

| Applicable Zones | Zone 1 & 2 gas hazardous areas |

| Zone 21 & 22 hazardous areas which contain conductive combustible dust | |

| Ambient working temperature | -40∼85℃ (use with SAFT LS26500) |

| Dimensions | H470xW100xD80 (included antenna) for hardware version 2 and H520xW100xD80 (included antenna) for hardware version 3 |

| Net-weight | ≈1500g (without battery) |

Dimension

Application Notes

Environmental Conditions: Consider the system environment (pipes, vibrations, temperature, etc.).

Pressure Range: Choose sensors that function well within the process range.

Precision and Sensitivity: Determine the required level of precision and sensitivity.