Only available for Logged-in member. Please login or register to access this information.Or use the Temporary User that we have provided to you via email.

expiry time

Item codes | FW Released Date | Changes Information |

|---|---|---|

WSLRW-BV-BR-20; WSLRW-BV-BR-25; WSLRW-BV-BR-08; WSLRW-BV-BR-15; | 05/02/2025 | Update valve type B for latching valve; Update limit of SF7 and ADR off for latching valve in frequency plan of US915, AU915, and IN865; Update LED operation for latching valve; Add configuration of CONTROL_PULSE_WIDTH for latching valve; Update possible values for PRODUCTION_FREQ_FACTOR _W_PASSWORD |

1

QUICK INSTALLATION GUIDE

1.1 Introduction

WSLRW-BV is a LoRaWAN Mini Control Valve, integrated with a Ball valve body. The ultra-low power design allows the Valve to run in 5 years with 2 batteries (depending on configuration). The valve will transmit data in kilo-meters distance to the LoRaWAN gateway, any brand on the market.

This LoRaWAN Mini Control valve is the best choice for an Irrigation System for a Garden, Smart Farm, or Hydroponic Farm. It can be used for FCU in HVAC or any water supply line in a Facility or Building.

How the sensor connect to system?

System components:

The end nodes are LoRaWAN Sensors or Actuators;

The Gateways are LoRaWAN Gateway or Base Station;

The Network Server can be SAAS or On-premise server;

The Application Server is the destination software users want to utilize the data from/ to LoRaWAN sensors/ actuators.

How to set up the LoRaWAN system? Please follow these steps:

Adding the Gateways to a Network server. Please refer to the manual of Gateway and Network Server software;

Adding the End nodes to the Network Server;

Configure the callback or data forwarding from the Network Server to the Application Software by MQTT or HTTPS. Please refer to the manual of the Network Server.

Once the payload is on the Application server, decode data from Payload. Please check Section 1.9 for the Payload document.

1.2 Application Notes

For Applications

Smart Irrigation, Water Supply System, Water Level Control, Oil Level Control

Notes

Flow Characteristic: Understand the desired Flow characteristic.

Valve Size: Choose Size based on the Flow rate and pipe diameter.

Noise and Cavitation: Evaluate the potential for Noise and cavitation.

Body and Trim Materials: Consider the fluid properties.

Actuator Type and Size: Ensure the Actuator can handle the required force and speed.

Dynamic Response: Assess how quickly the Valve responds to changes in the control signal.

1.3 When does device send Uplink messages?

The device will send uplink messages in the following cases:

Case 1: After power-up in the 60s, the device will send the first message called START_UP. The payload will tell the user the HW version, FW version, and current configuration of the device.

Case 2: Then, in every interval time (pre-configured), for example, 30 minutes, it will send the message called CYCLIC_DATA. The payload will tell the user the following data like measured values, battery level, and alarm status...

To change the cycle of data sending, you can change the value of the parameter: CYCLIC_DATA_PERIOD.

Case 3: The device will send ALARM message immediately when the valve control command switches from OPEN to CLOSE and vice versa. The alarm uplink contains information of valve control command (OPEN/CLOSE), total remaining schedule in the schedule queue, command status, schedule status, schedule start time, power supply/battery level, valve status, total open time, total close time, and control voltage.

Case 4: During the commissioning, testing, or calibration sensor, the user can force the device to send the uplink message to get the data immediately. This message is called FORCE_DATA. The payload will provide data like raw measured value, scaled measured values, battery level, and alarm status... It can be forced by applying the magnet key on the reed switch in 1s.

Case 5: If users want to change the configuration immediately, they don't need to wait until the next cyclic data-sending message; instead, they can force the device to send a special uplink message so that the device can get the new downlink message. This uplink message is named PARAMETERS_UPDATE. It can be forced by applying the magnet key in more than 5s.

Case 6: In every interval time (pre-configured), for example, 24 hours, it will send the message called HEARTBEAT. The payload will tell the user the following data like hardware version, firmware version, current sensor configuration.

Case 7: If LNS_CHECK_MODE =1, it will send the confirmed uplink message called LNS_CHECK every 24 hours. This confirmed uplink message is a message where a LoRaWAN device is requesting a LoRaWAN network to confirm the reception of its message. If the device receives no confirmation message from LoraWAN network server, it will re-send the LNS_CHECK message every hour during 3 hours. After 4th hour, if the device still receives no confirmation message, it will reset itself to join the network server. The LNS_CHECK payload will tell the user the following data like hardware version, firmware version, current sensor configuration.

Case 8: When the downlink type 2 of the control schedule is sent from Network Server/Gateway to device, the device will automatically send the SCHEDULE_ACK uplink message to confirm the successful receipt of the control schedule.

Case 9: If the application/network server sends downlink 3 to check current value of a configuration parameter or sends downlink type 4 or downlink type 5 to change value of a configuration parameter, the device will send the CONFIG-CHECK uplink. The payload of CONFIG-CHECK uplink contains the result of the configuration changes/configuration check.

1.4 Default Configuration

This device has the default configuration (opening and closing times), however, those parameters can be changed. The user can change the configuration on the wireless transmitter so that the complete sensor (transducer + wireless) delivers the proper output value. Please check the Payload document for more information.

1.5 Battery/ Power Supply

The Device uses below batteries:

Battery type: Primary battery

Battery size and Voltage: D 3.6 VDC

Number of batteries: 02

Recommended batteries: Saft LS33600

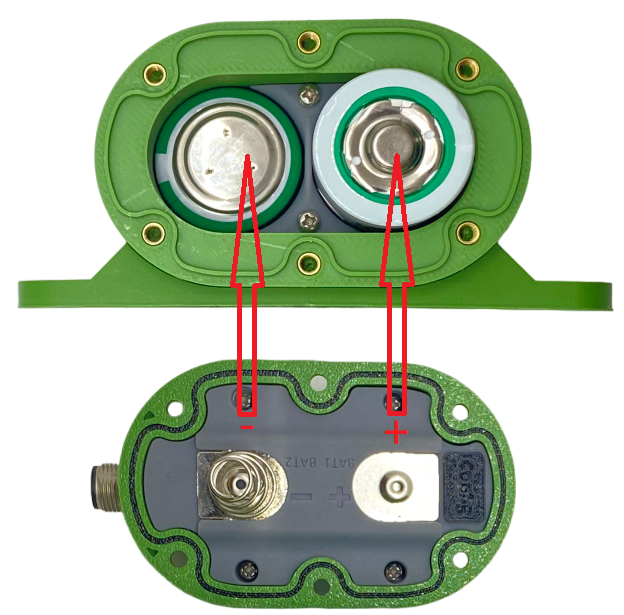

Battery Installation

Step 1: Open upper housing by unscrewing 6 screws

Step 2: Identify the correct battery polarity

Step 3: Insert 2 D-batteries with correct polarity

Step 4: Close the upper housing and fixed with 6 screws. Please take note of the Parity of the batteries as shown inside the upper housing

Understanding the battery levels:

Level 3 (4 bars): battery energy is 60-99%

Level 2 (3 bars): battery energy is 30-60%

Level 1 (2 bars): battery energy is 10-30%

Level 0 (1 bar): battery energy is 0-10%

Note: to display accurately the remaining energy of the battery, please configure the correct BATTERY_TYPE by downlink type 5 or offline cable. Please check the section Principle of Operation for more details.

1.6 What's in the Package?

1.7 Guide for Quick Test

With the default configuration, the device can be connected quickly to the Network Server by the following steps.

Step 1: Prepare the values of communication settings

Frequency zone: Most of the sensor was configured the frequency zone to suit customer application before delivery

DevEUI: Get the DevEUI on the product nameplate

AppEUI Default value: 010203040506070809

AppKey Default value: 0102030405060708090A0B0C0D0E0F10

Activation Mode: OTAA with local join server

Network Mode: Public

LoraWAN Protocol: version1.0.3

Class: A for sensor; C for actuator

If current basic common settings do not match with your region, network server/application, follow below instruction to change them as below:

NOTE: If the settings in above table are changed via downlink, the device MUST be reset to make the changed settings take effect. The reset is hard reset (Turn OFF external power supply, wait 3-7 minutes, and then turn ON external power supply OR take out battery, wait 3-7 minutes and then insert battery back ) OR soft reset via downlink 0. Downlink 0 hexadecimal value to reset device equal CURRENT_CONFIGURATION hexadecimal value in uplink but change the 15th value of the CURRENT_CONFIGURATION from 0 to A. For example, CURRENT_CONFIGURATION is 00C80064000B6000, the downlink 0 value for resetting device will be 00C80064000B60A0

For changing other settings, please refer to Section 3.2 Sensor configuration to change the other settings

Step 2: Register the device on the LoRaWAN network server

Input the above settings on your device registration page of the network server.

Note: Different network server software will have different device registration processes. Please refer to the manual of the network server software used for more details.

Please visit the below Section 1.10 to get the instructions for adding the LoRaWAN sensors to some common network servers such as Actility, TTN...

Step 3: Install the batteries to the device OR do power wiring and supply external power to the device if applicable

Please refer to Section 1.5 as above for instructions on battery installation OR for instructions to do power wiring and supply external power to the the device if applicable

After installing the battery in 60 seconds, the first data packet will be sent to the LoRaWAN gateway. After receiving the first data packet, the time of another packet depends on the value of the parameter: cycle_send_data. Additionally, you can use a magnet key to touch the magnetic switch point on the housing within 1 second to initiate force packet of the device to send data instantly and the LEDs on the housing will be lit with SKY BLUE color.

Step 4: Decode the payload of receiving package

Please refer to Section 1.9 Payload Document and Configuration Tables for details of decoding the receiving packet to get the measured values.

If the device has local display, measured values are shown on the local display

1.8 Installation

Dimension Drawings and Installation Gallery (Photos and Videos)

Please follow the checklist below for a successful installation:

1. Have you studied the dimensions of the device as above drawings?

2. Have you tested and make sure the device have been connected successfully as Section "1.7 Guide for Quick Test" above?

3. Have the device been configured properly as per Section 3.2 below?

4. Have the device been calibrated or validated as per Section 3.3 below?

5. Then you can start to install the device at site. Please check the following Installation Notes for Sensor Part (if available) before installation.

Installation Notes for Sensor Part (if available)

Installation Notes for Ball Valves

1. Preparation:

Power Supply: Ensure the power supply matches the voltage and current requirements of the valve.

Tools: Gather necessary tools such as a multimeter, screwdriver, wire strippers, and connectors.

2. Mounting:

Location: Choose a clean, dry, and accessible location for the controller.

Secure Mounting: Mount the controller securely using screws or brackets.

3. Electrical Connections:

Polarity: Ensure correct polarity for the electrical connections. Use an H-bridge circuit if needed for polarity reversal.

Wiring: Connect the controller to the solenoid valve using appropriate gauge wires. Secure connections with wire nuts or terminal blocks.

Power Supply: Connect the power supply to the controller, ensuring it is turned off during installation.

4. Configuration:

Pulse Duration: Set the pulse duration on the controller to match the requirements of the valve.

Programming: If using a programmable controller, configure it to send the correct pulse duration and polarity.

5. Testing:

Initial Test: Turn on the power supply and test the controller to ensure it switches the valve correctly.

Adjustments: Make any necessary adjustments to the pulse duration or configuration settings.

6. Final Checks:

Secure Connections: Double-check all electrical connections to ensure they are secure and properly insulated.

Environmental Conditions: Verify that the installation can withstand the expected environmental conditions (e.g., temperature, humidity).

7. Documentation:

Record Settings: Document the configuration settings and any adjustments made during installation.

Maintenance Schedule: Establish a maintenance schedule to periodically check the controller and valve for proper operation.

Installation Guide for Main Device

Check the Location for the best RF Signal

Make sure the site is good enough for RF signal transmission.

Tip: To maximize the transmission distance, the ideal condition is Line-of-sight (LOS) between the LoRaWAN sensor and the gateway. In real life, there may be no LOS condition. However, the LoRaWAN sensor still communicates with the gateway, but the distance will be reduced significantly.

DO NOT install the wireless sensor or its antenna inside a completed metallic box or housing because the RF signal can not pass through the metallic wall. The housing is made from Non-metallic materials like plastic, glass, wood, leather, concrete, and cement…is acceptable.

Mounting the Valve body on the pipe

Locate the position to mount the valve body so that the distance from the valve body to the wireless part is less than 2m cable length.

Mounting the Wireless part on the Wall or Pole

Mount the Wireless part onto a wall by the mounting bracket as shown picture below.

1.9 Payload Document and Configuration Tables

Please click below button for:

-

Payload decoding of Uplink messages;

-

Payload encoding of Downlink messages;

-

Configuration Tables of device.

Note:

If the content of below web payload, memory map, and sample decoder could not be copied, please install the extension of "Enable Copy Paste - E.C.P" for Microsoft Edge and for Google Chrome.

1.10 How to connect device to Back-end/ Network Server/ Coordinator

Please find below the examples of adding Daviteq's LoRaWAN sensor to the following Network servers:

ThingPark Community (of Actility);

Things Stack (of The Things Network).

You can use the similar methods to add LoRaWAN sensors to other Network Server.

1. THINGPARK COMMUNITY (ACTILITY) NETWORK SERVER

1.1. Example to add the Tektelic LoraWAN gateway Model T0005204 to ThingPark Enterprise SaaS Community

1. Log in to your ThingPark Enterprise account via the link: https://community.thingpark.io/tpe/

2. Browse on the left panel to Base Stations, click the drop-down menu, then click Create.

3. Select the base station’s Tektelic.

※ If you do not find the Tektelic, click View More Manufacturers.

4. On the following screen, select the Model: Micro 8-channels from the drop-down list.

5. Fill the form as below table:

Input exactly as above Input field column, except Name field is user-defined and is different from the existing base station name on the network server.

After filling the registration form, click CREATE to complete adding the base station to the network server.

1.2. Add Daviteq's LoRaWAN devices to ThingPark Enterprise SaaS Community

ThingPark Enterprise supports all Classes of LoRaWAN® devices. By default, the sensor supports Over-the-Air Activation (OTAA) with a local Join Server that is programmed at the factory.

Manual provisioning of OTAA devices using a local Join Server. To learn more, see Activation modes.

1. At left panel of the screen of the Thingpark GUI, click Devices > Create from the dashboard.

2. Select the Generic supported by your device on your screen.

3. Select the Model of LoRanWAN 1.0.3 revA - class A with correct frequency plan

4. Fill the form as below table:

In addition to filling out the form, the option to select the connection between ThingPark and Daviteq application (Globiots).

After filling out the registration form, please click CREATE to add devices to the network server.

1.3. Send a downlink frame from Thingpark Network Server to the device

Follow the below steps to send the downlink frame from Thingpark Network Server to the device:

This functionality is active only when a connection is associated to the device (one of the color codes with a green bullet).

1. Navigate to the left panel, click the Devices' drop-down menu, then click List.

2. Browse the right side in the Devices, click the icon of the device and click Send Downlink.

3. Input the downlink code to the Payload field and input 1 to the Port field, and then click Validate.

The downlink data is added to the device downlink queue in network server. The downlink is sent after the network server receive an uplink from the device.

2. THINGS STACK (THE THINGS NETWORK) NETWORK SERVER

2.1. Add Sentrius LoraWAN gateway (Model RG19) to The things Stack network server

1. Log in to you’re The Things Stack account

2. Click the tab Gateways, click Add gateway button

3. Fill out the form as below table:

Input exactly as above Input column, except the Gateway Name field and the Gateway ID field is user-defined. It is different from the existing gateway name and gateway ID on the network server.

After filling the registration form, click Create gateway to complete adding the base station to the network server.

2.2. Add Daviteq's LoRaWAN device to The Things Stack network server

The Things Stack supports all Classes of LoRaWAN® devices. By default, the sensor supports Over-the-Air Activation (OTAA) with a local Join Server programmed at the factory.

1. Browse on the top panel, click the tab Application, and click Add application button to create an application

2. Fill in the information fields as user-defined, then select Create application

3. After the application is created successfully, select Add end device to register end device (LoRaWAN sensor)

4. Fill out the form as below table:

After filling out the registration form, please click the Register end device button to add the device to the network server.

2.3. Send a downlink frame from The Things Stack Network Server to the device

1. Select the device to send downlink

2. Input 1 to the FPort and input the downlink data in the payload field, and then tick Confirmed downlink and click Schedule downlink.

2

MAINTENANCE

2.1 Troubleshooting

Please find below steps to identify the problems from Communication Part or Sensor Part:

* If the device cannot connect to the Gateway or System or Co-ordinator at the first time, it is the Communication Problem;

* If the device status like battery, RSSI level, data status or other communication is normal, but the measured values are not updated or wrong, it would be the problems of Sensor part;

* If the data coming to gateway, system or co-ordinator is not frequently as expected, the problem would be Communication.

Please refer below the troubleshooting guide for Communication and Sensor Part.

Troubleshooting for Communication

Troubleshooting for Sensor Part (if available)

1. Valve take longer time to open and close

Check inside status of valve

Check fluid pressure

Check voltage of power supply for actuator mechanism

2. Valve could not be open and close completely

Check any object stuck inside the valve

Check the ball erosive wear, ball deformation

3. Valve could not open/close as control command

Check object that could lock the ball of the valve

Check cable from control module to valve

2.2 Maintenance

Maintenance for Main device

There is no requirement for maintenance of the Hardware of this LoRaWAN Device except for the following:

1. The battery needs to be replaced. Please check the battery status via uplink messages;

Note: When the battery indicator shows only one bar (or 10% remaining capacity), please arrange to replace the battery with a new one as soon as possible. If not, the battery will drain completely, and the resulting chemical leakage can cause severe problems with the electronic circuit board.

2. Sensor, please refer to the maintenance section of the sensor document.

Maintenance for Sensor part (if available)

Re-calibration:

Once the error code appears on the system, please perform the calibration of opening and closing time to make sure the valve opens and closes completely, and no passing problem happens.

Valve body replacement:

Replace the new valve body.

3

ADVANCED GUIDE

3.1 Principle of Operation

Principle of Operation for device WSLRW-BV | FW5

Daviteq LoraWAN Mini Motorized Ball Valve (BV) comprises 02 parts linked internally:

• The Daviteq LoraWAN wireless transmitter;

• The Daviteq Mini Motorized Ball Valve (BV)

What are the primary output values?

• VALVE CONTROL COMMAND: Valve control command. This parameter equals VALVE_CONTROL_COMMAND in the uplink payload

• VALVE STATUS: Valve status. This parameter equals VALVE_STATUS in the uplink payload

• NRS COUNTER ON: Non-resettable counter values for the valve open command. This parameter equals NRS_COUNTER_ON in the uplink payload

• NRS TIMER ON: Non-resettable timer values for the valve open status, unit of second. This parameter equals NRS_TIMER_ON in the uplink payload

• OPEN TIME: The period of the opening of the valve, unit of second. This parameter equals OPEN_TIME in the uplink payload

• CLOSE TIME: The period of the closing of the valve, unit of second. This parameter equals CLOSE_TIME in the uplink payload

• VALVE CONTROL VOLTAGE: The power supply for the valve, unit of Volt. If VALVE_CONTROL_VOLTAGE less than 4.5 vdc, the device will be reset. This parameter equals VALVE_CONTROL_VOLTAGE_X10 in the uplink payload divided by 10

• SCHEDULE CONTROL COMMAND: Schedule's control command: open valve/close valve/clear schedule queue. This parameter equals SCHEDULE_CONTROL_COMMAND in the uplink payload

• SCHEDULE START TIME: Schedule's start time for open valve/close valve, in format of epoch time since 1/1/2020 00:00:00 GMT+0. It represents the number of seconds that have elapsed since January 1, 2020 00:00:00 GMT+0. If SCHEDULE_START_TIME equals zero, the control command will be implemented immediately and the schedule will not be put into the sensor memory queue. This parameter equals SCHEDULE_START_TIME in the uplink payload

• SCHEDULE DURATION: Schedule's duration for open valve/close valve command, unit of second. If the duration equal zero, the command will be implemented until next control command. This parameter equals SCHEDULE_DURATION in the uplink payload

• SCHEDULE ORDINAL NUMBER: Schedule's ordinal number in the valve's memory queue. If the SCHEDULE_START_TIME equal 0, the SCHEDULE_ORGINAL_NUMBER will be equal zero. This parameter equals SCHEDULE_ORDINAL_NUMBER in the uplink payload

• TOTAL SCHEDULE: Total available schedules in the valve memory queue. This parameter equals TOTAL_SCHEDULE in the uplink payload

• SCHEDULE STATUS: Schedule implementation status (started, complete). This parameter equals SCHEDULE_STATUS in the uplink payload

What are the secondary output values?

Below output values are useful for device maintenance and troubleshooting.

• Power supply level (%): the remaining capacity of the battery OR external power supply voltage level. The parameter in the payload is POWER_SUPPLY_LEVEL.

• Alarm: alarm status of the device. The parameter in the payload is ALERT_STATUS

• Sensor current configurations: current main settings of the sensor and this parameter in the payload is CURRENT_CONFIGURATION

• Sensor hardware version: hardware version of the sensor and this parameter in the payload is HW_VERSION

• Sensor firmware version: firmware version of the sensor and this parameter in the payload is FW_VERSION

• Valve type: Type of the valve body (0 = None/ 1 = Type A/2= Type B (Latching valve)). This parameter equals VALVE_TYPE in the uplink payload

Principle of operation

Device power on / power reset/ reed switch operation

When the device is power on or power reset, the VALVE CONTROL COMMAND will equal DEFAULT_COMMAND. DEFAULT_COMMAND might have one of following values:

1: Command to open valve

2: Command to close valve (default value)

3: Last control command.

If the last control command is different from DEFAULT_COMMAND, the DEFAULT_COMMAND control command will be implemented and ALARM uplink message will be sent to Network Server after the control command implementation is completed. The result of control is ALERT_STATUS and might be one of following:

1: successfully opened event (The real period of opening valve is less than or equal VALVE_OPENING_TIME)

2: successfully closed event (The real period of closing valve is less than or equal VALVE_CLOSING_TIME)

3: valve cable or connector error

4: duplicated control command (The current control command is the same as last control command)

5: stuck valve at opening (The real period of opening valve is greater than VALVE_OPENING_TIME + VALVE_DIAGNOSTIC_PERIOD)

6: stuck valve at closing (The real period of closing valve is greater than VALVE_CLOSING_TIME + VALVE_DIAGNOSTIC_PERIOD)

7: valve tend to get stuck at opening (The real period of opening valve is greater than VALVE_OPENING_TIME and less than or equal VALVE_OPENING_TIME + VALVE_DIAGNOSTIC_PERIOD)

8: valve tend to get stuck at closing (The real period of closing valve is greater than VALVE_CLOSING_TIME and less than or equal VALVE_CLOSING_TIME + VALVE_DIAGNOSTIC_PERIOD)

To reset the device via reed switch, use magnetic key to touch reed switch point on the housing during 5 seconds as below

Scheduled control

Principle of scheduled control

In addition to instant control functions, the new version of valve enables scheduled control that is configured in real time, allowing for up to 15 control commands to be stored in memory.

The necessary steps involve synchronizing the real-time clock for the valve and setting up control schedules. Configuring the real-time clock for the valve is set through Downlink type 5, and scheduled control commands for valve are set through Downlink type 2. These control commands will be stored in the valve’s memory and executed when the start time of a command matches the real-time.

Configure the Real-Time Clock

The device has its own real-time clock. The real-time clock only runs when the device is powered by batteries. The value of the real-time clock increases by 1 every second. The device schedule in device queue operate based on device real-time clock. When start time of the schedule in the queue equals to the value of device's real-time clock, the schedule's command will be implemented. If the device is disconnected from the batteries, the current real-time clock value will be stored in EEPROM. If the device is connected to batteries again, the device read the stored time clock value in the EEPROM, assign this value to real-time clock and the real-time clock start to run ( increase by 1 every second).

When device receives downlink to write the value to SYNC_E_TIME parameter/configuration/setting on the memory device, the device will write the time value in the downlink to the SYNC_E_TIME parameter as well as write this value to the device's real-time clock. The downlink for SYNC_E_TIME should be sent after the the device is power up OR/AND before the schedule's downlink is sent. SYNC_E_TIME value remains in the memory when the valve is disconnected from the battery

Use downlink type 5 to set the real-time clock on the valve. This step is crucial for ensuring that the valve operates according to the correct time. The Real-time clock is Synchronized time from network server, in format of Epoch time since 1/1/2020.

The synchronized time is equal difference in seconds between current time and original point (00:00:00 01/01/2020)

Example: the current time is 12:00:00 29-04-2024 so the synchronized time is 136555200 (Decimal) = 0823AAC0 (Hex)

Free online tool to calculate the difference between two dates:

https://www.epochconverter.com/date-difference

Use downlink type 5 to write synchronized time to parameter SYNC_E_TIME of valve.

Here is the format of downlink type 5:

Example: the current time is 12:00:00 29-04-2024 so the synchronized time is 136555200 (Decimal) = 0823AAC0 (Hex)

The final downlink payload of example is 63040823AAC00005

Note:

• The real-time clock may run inaccurately when the valve loses power from its battery. Therefore, we recommend periodically synchronizing the real-time clock, ideally before scheduling control commands for the valve.

• According to the principles of LoRaWAN network, the valve will received a downlink message after it sends an uplink message. Therefore, it’s necessary to determine the timing of when the valve sends an uplink message in order to calculate the synchronized time accurately. For example, if you intend to send a downlink to synchronize the time at 9:30, but according to the cycle, the valve only sends an uplink at 10:00, then you must use the synchronized time at 10:00 to calculate synchronized time in downlink.

Set Up Control Commands

Use downlink type 2 to send control commands to the valve. These commands include the specific parameters you want the valve to perform. Here is the format of Downlink type 2

SCHEDULE_START_TIME (0-4294967296):

Schedule's start time for SCHEDULE_CONTROL_COMMAND, in format of epoch time since 1/1/2020 00:00:00 GMT+0. It represents the number of seconds that have elapsed since January 1, 2020 00:00:00 GMT+0. If SCHEDULE_START_TIME equal zero, the control command will be implemented immediately and the schedule will not be put into the sensor memory queue. The synchronized time in downlink from the network server must be also in the same format as one of SCHEDULE_START_TIME.

- SCHEDULE_DURATION (0-65536):

Schedule's duration for open valve/close valve command, unit of second. If the duration equal zero, the command will be implemented until next control command.

- Reserved: Reserved for future usage

- SCHEDULE_CONTROL_COMMAND (1: open valve ; 2: close valve; 3: clear all schedule in queue)

Schedule's control command: open valve/close valve/clear schedule queue.

Example 1:

Create a schedule control command to open the valve at 11:30:00 on April 29, 2024, then close the valve after 60 minutes.

SCHEDULE_START_TIME = 136553400 (DEC) = 0823A3B8

SCHEDULE_DURATION = 3600(DEC)= 0E10 (HEX)

Reserved: 00 (HEX)

SCHEDULE_CONTROL_COMMAND = 1

DOWNLINK_TYPE = 2

FINAL DOWNLINK : 0823A3B80E100012

Example 2:

Create a schedule control command to open the valve immediately upon receiving the downlink, then close the valve after 30 minutes.

SCHEDULE_START_TIME = 00000000 (DEC) = 00000000 (HEX)

SCHEDULE_DURATION = 1800(DEC)= 0708 (HEX)

Reserved: 00 (HEX)

SCHEDULE_CONTROL_COMMAND = 1

DOWNLINK_TYPE = 2

FINAL DOWNLINK : 0000000007080012

Example 3:

Create a control command to open the valve at 13:00:00 on April 29, 2024, then keep it open until the next control command.

SCHEDULE_START_TIME = 136558800 (DEC) = 0823B8D0 (HEX)

SCHEDULE_DURATION = 0000(DEC)= 0000 (HEX)

Reserved: 00 (HEX)

SCHEDULE_CONTROL_COMMAND = 1

DOWNLINK_TYPE = 2

FINAL DOWNLINK : 0823B8D000000012

Example 4:

Create a downlink to clear all schedule commands in valve’s memory

SCHEDULE_START_TIME = 00000000 (DEC) = 00000000 (HEX)

SCHEDULE_DURATION = 0000(DEC)= 0000 (HEX)

Reserved: 00 (HEX)

SCHEDULE_CONTROL_COMMAND = 3

DOWNLINK_TYPE = 2

FINAL DOWNLINK : 0000000000000032

Example 5:

Create a control command to open the valve immediately upon receiving the downlink, then keep it open until the next control command.

SCHEDULE_START_TIME = 00000000 (DEC) = 00000000 (HEX)

SCHEDULE_DURATION = 0000(DEC)= 0000 (HEX)

Reserved: 00 (HEX)

SCHEDULE_CONTROL_COMMAND = 1

DOWNLINK_TYPE = 2

FINAL DOWNLINK : 0000000000000012

Example 6:

Create a control command to close the valve immediately upon receiving the downlink, then keep it close until the next control command.

SCHEDULE_START_TIME = 00000000 (DEC) = 00000000 (HEX)

SCHEDULE_DURATION = 0000(DEC)= 0000 (HEX)

Reserved: 00 (HEX)

SCHEDULE_CONTROL_COMMAND = 2

DOWNLINK_TYPE = 2

FINAL DOWNLINK : 0000000000000022

Note:

• The schedule control commands will be stored in the memory of the valve and executed in chronological order base on the SCHEDULE_START_TIME.

• The maximum number of schedule control commands is 15. If the number of commands exceeds 15, the valve will automatically delete the earliest commands and overwrite them with new ones.

• Two schedules are defined as duplicate if their start times are the same. When a schedule duplicate with another schedule in memory, the latter schedule will overwrite the former one

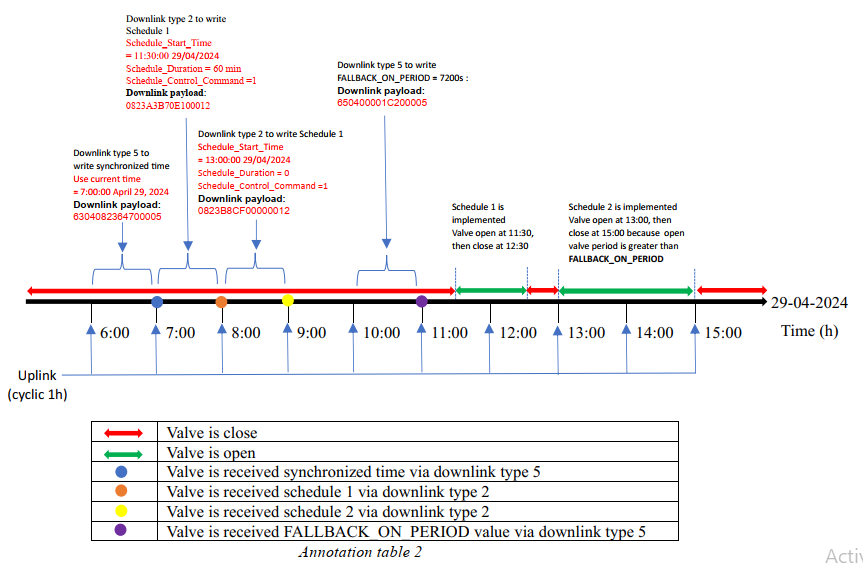

Example of Multi-scheduled Control

*Default configuration:

➢ The valve is configured with an uplink transmission cycle of 1 hour, and

uplinks are sent precisely at even hours.

➢ The default state of the valve is closed.

*Demand: To configure the valve to automatically open twice:

➢ The first opening will be from 11:30 to 12:30 on April 29, 2024.

➢ The second opening will be from 14:00 to 14:30 on April 29, 2024.

Note:

The period between downlinks must be equal OR greater than cyclic period to ensure all downlinks will be received by the valve

The downlink process need strong LoRaWAN signals than uplink process

Fallback control

Principle of Fall-back control

With this function, we can limit the maximum opening time or the maximum closing time of the valve. Here are two parameters that can be set for this function:

• FALLBACK_ON_PERIOD

Maximum allowable period for open valve, unit of second. If the open valve period is greater than FALLBACK_ON_PERIOD, the valve will be closed automatically and the alarm event will occur. If FALLBACK_ON_PERIOD =0, no fallback function for open valve is available

• FALLBACK_OFF_PERIOD

Maximum allowable period for close valve, unit of second. If the close valve period is greater than FALLBACK_OFF_PERIOD, the valve will be opened automatically and the alarm event will occur.

If FALLBACK_OFF_PERIOD =0, no fallback function for close valve is available

Use downlink type 5 to set FALLBACK_ON_PERIOD or FALLBACK_OFF_PERIOD.

Here is an example of downlink for Fallback function.

FALLBACK_ON_PERIOD = 7200s (DEC) = 00001C20 (HEX)

FALLBACK_OFF_PERIOD = 3600s (DEC) = 00000E10 (HEX)

Example of Fall-back control

• Default configuration:

➢ The valve is configured with an uplink transmission cycle of 1 hour, and uplinks are sent precisely at even hours.

➢ The default state of the valve is closed.

• Demand: To configure the valve to automatically open twice:

➢ The first opening will be from 11:30 to 12:30 on April 29, 2024.

➢ The second opening will be at 14:00 at April 29, 2024, then keep it open until the next control command

➢ The valve only allows a maximum opening time of 2 hours (FALLBACK_ON_PERIOD = 7200s)

LED indication

There are 3 LEDs on the housing:

COM LED: lit when there is any uplink. The color of the LED is based on uplink type. Refer the PAYLOAD AND MEMORY MAP DOCUMENT for LED color of each uplink type.

OPEN LED: Blink every 5 second if the valve status is open.

CLOSE LED: Blink every 5 seconds if the valve status is close.

Principle of Operation of Sensor part (if available)

This mini-control valve is a 2-piece design ball valve with a low torque feature to allow the valve to use less energy than the regular valve on the market. This feature allows the valve to be operated by batteries for years.

The ball will be moved by the internal micro motor and a set of micro limit switches to allow the running from 0° to 90° of opening.

The valve will be powered and controlled from a wireless device, it could be LoRaWAN, Sigfox, NB-IoT, or Sub-GHz technology.

Default Configuration Parameters of Sensor part (if available)

This device has the default configuration (opening and closing times), however, those parameters can be changed. The user can change the configuration on the wireless transmitter so that the complete sensor (transducer + wireless) delivers the proper output value. Please check the Payload document for more information.

3.2 Configuration

How to configure the device?

Sensor configuration can be configured in 02 methods:

Method 1: Configuring via Downlink messages, port 1 (default)

Method 2: Configuring via Offline cable

To access to the configuration port, open the upper housing by unscrewing 6 screws as below figures:

Take out the upper housing, the position of configuration port on the upper housing as below figure

Note:

The sensor is only active for offline configuration in the first 60 since power up by battery or plugging the configuration cable.

Note the battery polarity on the upper housing for right direction during re-installation of the upper housing.

Which Parameters are configured?

Please check Part G in Section 1.9 Payload Documents above.

Method 1: Configuration via Downlink messages

Please check the Part D & E in Section 1.9 Payload Documents above.

Method 2: Configuration by Offline Cable

Please download the Configuration Template File of this sensor to be used in Step 4 below.

Instructions for offline configuration of the Daviteq LoRaWAN sensors. Please follow the following steps.

Note: The sensor is only active for offline configuration in the first 60 since power up by battery or plugging the configuration cable.

1. Prepare equipment and tools

The following items must be prepared for configuration.

A PC using the Windows OS (Windows 7 or above versions). The PC installed the COM port driver of the Modbus configuration cable (if needed). The driver is at link: Modbus Configuration Cable COM port driver for PC and the instruction to install the driver at link: How to install the driver.

A Modbus configuration cable

Tools to open the plastic housing of LoRaWAN sensors (L hex key or screwdriver)

2. Download and launch Daviteq Modbus configuration software

Click the link below to download Daviteq Modbus configuration software:

https://filerun.daviteq.com/wl/?id=yDOjE5d6kqFlGNVVlMdFg19Aad6aw0Hs

After downloading the software, unzip the file named: Daviteq Modbus Configuration.zip and then copy the extracted folder to the storage drive for long-term use.

Open the folder, double click on the file Daviteq Modbus Configuration Tool Version.exe to launch the software and the software interface as below:

Note: The software only runs on Microsoft Windows OS (Windows 7 and above).

3. Connect the cable and configure the sensor

Step 1:

Connect the PC to the sensor using the configuration cable.

- Use the configuration cable (Item code: TTL-LRW-USB-01).

- Connect the USB-A plug into the USB-A socket of the PC.

Step 2:

On the configuration software, choose the relevant Port (the USB port which is the cable plugged in) and set the BaudRate: 9600, Parity: none

Step 3:

Click Connect button to connect the software to the sensor. After successful connection, the Connected status will show on the software.

Step 4:

Import the configuration template file of the sensor (as above link) to the software: click menu File/ Import New and then browse the relevant sensor template file (csv file) and click Open to import the template file.

Note: The sensor is only active for configuration for 60 seconds since plugging the configuration cable or the power supply into the sensor.

Each sensor type has its own template file. Refer to the sensor's manual to download the correct file.

Step 5:

Open the housing of the sensor and quickly plug the connector of the configuration cable into sensor's modbus configuration port as below figure. After plugging the connector, the software will read the parameter values automatically.

Plug the cable connector into sensor's modbus configuration port. This port is located at a different location, depends on the sensor type

Note: If the sensor has SKU of WSLRWEX-PPS and hardware version 1 & 2, the sensor must be powered by batteries for configuration

Step 6:

Read the current value of the parameter with Modbus Function 3

At the relevant row of the parameter, check box 3 on column Func to read the value of the parameter. The read value is shown in VALUE ON MEMMAP column.

The sensor is only active for configuration for 60 seconds since plugging the configuration cable or the power supply into the sensor. After 60 seconds, the TIME_OUT text will show on EXCEPTION column of the software.

Step 7:

Write the new setting to the parameter with Modbus Function 16

Double click on the column VALUE TO WRITE of the parameter and input the new setting value of the parameter;

Uncheck the tick on the FC column of the parameter, click on the arrow, select 16 and then check on the FC column to write a new setting to the parameter. The WRITE_OK text will show on EXCEPTION column if the software successfully writes the setting.

Repeat Step 6 to read the setting of the parameter for double-checking.

Note: For some critical parameters of the sensor, the password in "password for setting" must be written before writing the new settings to these parameters.

Only read/ write registers are allowed to write.

The sensor is only active for configuration for 60 seconds since plugging the configuration cable or the power supply into the sensor. After 60 seconds, the TIME_OUT text will show on EXCEPTION column of the software.

4. Troubleshooting

3.3 Calibration/ Validation

How to force sensor to send data for calibration/ validation (if available)

Using the magnet key, the device can be triggered to send data to the Gateway immediately. Touch the magnet key to magnetic point on the device housing within 1 second to trigger sending force message.

Note:

Upon transmitting the data to the base station using the magnetic key, the timer for the transmission time interval will be reset.

The minimum time interval between two manual triggers is 15 seconds. If the interval is less than 15 seconds, data transmission will not occur.

Don't use the magnetic key to touch the lower reed switch reset magnetic point for forcing data. This lower magnetic point is to reset the LoRaWAN device.

Calibration/ Validation sensor (if available)

The mini-control valve is calibrated at the factory to make sure it will close or open completely.

However, after time of usage, the closing and opening times will be increased a bit due to the friction between the ball and the seat increase. Users can check these values from the diagnostic feature of the device and adjust accordingly. Users can use the offline tool or downlink to write the new values of maximum allowable valve open time and maximumu allowable valve close time

4

PRODUCT SPECIFICATIONS

4.1 Specifications

Spec

5

WARRANTY & SUPPORT

5.1 Warranty

Warranty

Below terms and conditions are applied for products manufactured and supplied by Daviteq Technologies Inc.

Free Warranty Conditions

The manufacturer undertakes to guarantee within 12 months from shipment date.

Product failed due to defects in material or workmanship.

Serial number, label, warranty stamp remains intact (not purged, detected, edited, scraped, tore, blurry, spotty, or pasted on top by certain items).

During the warranty period, if any problem of damage occurs due to technical manufacturing, please notify our Support Center for free warranty consultancy. Unauthorized treatments and modifications are not allowed.

Product failed due to the defects from the manufacturer, depending on the actual situation, Daviteq will consider replacement or repairs.

Note: One way shipping cost to the Return center shall be paid by Customers.

Paid Warranty

The warranty period has expired.

The product is not manufactured by Daviteq.

Product failed due to damage caused by disasters such as fire, flood, lightning or explosion, etc.

Product damaged during shipment.

Product damaged due to faulty installation, usage, or power supply.

Product damage caused by the customer.

Product rusted, stained by effects of the environment or due to vandalism, liquid (acids, chemicals, etc.)

Product damage is caused by unauthorized treatments and modifications.

Note: Customers will be subjected to all repairing expenses and 2-way shipping costs. If arises disagreement with the company's determining faults, both parties will have a third party inspection appraise such damage and its decision be and is the final decision.

5.2 Support

Support via Help center

If you need our support for Daviteq device's installation, configuration, test, and decode, please input support request at link: https://forms.office.com/r/XWHbYG7yy7

Our support engineer will contact you via email or the support ticket system.

If you have any questions about the product, you can search for information on our web (https://www.iot.daviteq.com/). If you can't find the right information, please register an account and send us a request at link Contact us | Daviteq Technologies . We will respond within 24 hours.