The Role of IoT in Industrial Automation

- Nguyen Nhut Quy

- Jul 10, 2025

- 10 min read

Updated: Aug 15, 2025

In today’s rapidly evolving manufacturing landscape, automation is no longer a luxury—it’s a necessity. For operations managers, engineers, and plant leaders, the pressure to reduce downtime, improve efficiency, and unlock data-driven insights is stronger than ever.

While traditional automation systems have brought gains in productivity, they often lack the flexibility and intelligence required in modern smart factories. This is where the Industrial Internet of Things (IIoT) comes in—with wireless sensor networks and in-time data unlocking new levels of control and insight.

In this article, we explore how industrial automation and IoT are converging to reshape manufacturing—from predictive maintenance to energy optimization—and how solutions like wireless sensors are helping factories take their first step into Industry 4.0.

What Is Industrial Automation and Why It Matters Today?

Industrial automation refers to the use of control systems—such as computers, PLCs, and intelligent sensors—to operate machinery and processes with minimal human intervention. Its purpose is straightforward: to improve productivity, accuracy, and safety while reducing costs and operational risks.

For decades, automation has been a driving force behind manufacturing efficiency. Fixed automation systems have streamlined repetitive tasks, increased throughput, and helped manufacturers meet growing demands with fewer errors. However, these systems are often rigid, siloed, and slow to adapt to changing production needs. Today, as factories face tighter margins, more complex supply chains, and higher customer expectations, the old model of automation isn’t enough. The next evolution requires intelligence and flexibility—the ability to collect, interpret, and act on in-time data from every corner of the production floor.

This is where IoT—and more specifically, Industrial IoT (IIoT)—adds a transformative layer to automation. By connecting machines, sensors, and software into an integrated ecosystem, factories gain visibility not just into how things are operating, but why. And with that insight, operations managers can move from reactive problem-solving to proactive optimization.

The Rise of IoT in Industrial Settings

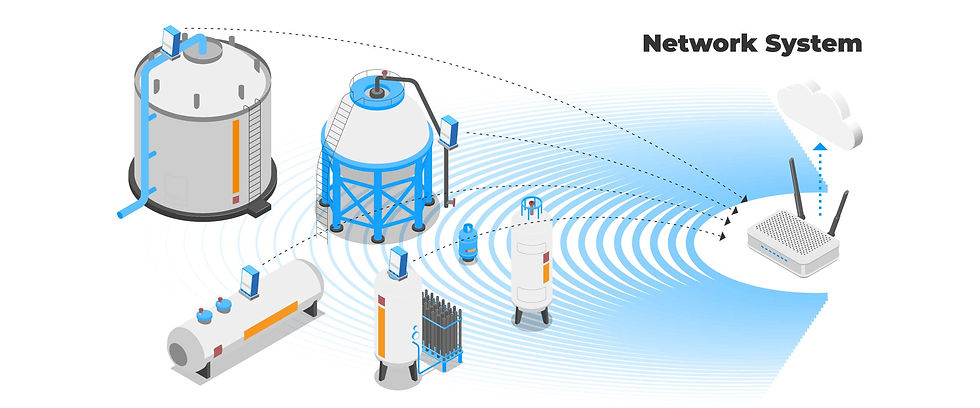

The Industrial Internet of Things (IIoT) marks a major shift in how factories operate. Instead of relying solely on programmable logic controllers (PLCs) and fixed automation rules, IIoT introduces a new layer of intelligence—one where machines, assets, and environments are interconnected and continuously communicating.

At the core of this transformation are smart sensors that collect operational data—such as temperature, vibration, pressure, and energy consumption—from critical equipment. When connected via wireless protocols like LoRaWAN, NB-IoT, or LTE-M, these sensors form a distributed network that can feed in-time data to centralized platforms for monitoring, analysis, and decision-making.

This enables industrial teams to:

Monitor processes remotely and proactively

Detect anomalies before failure occurs

Optimize energy usage in a timely manner

Make faster, data-backed operational decisions

Unlike legacy systems that are often siloed and expensive to expand, IIoT systems are modular and scalable. Wireless sensors can be easily deployed without disrupting production, making it feasible to digitize even hard-to-reach assets or remote facilities.

For leaders, this means more control, greater visibility, and faster response times—without overhauling the entire factory infrastructure.

Key Benefits of IoT-Powered Industrial Automation

Integrating IoT into industrial automation isn’t just about collecting more data—it’s about unlocking actionable insights that drive measurable improvements across your operations. Below are key benefits that manufacturers are realizing through IIoT systems powered by wireless sensors.

Predictive Maintenance

Traditional maintenance schedules are either time-based or reactive, both of which lead to unnecessary costs or unexpected downtime. With IoT-enabled condition monitoring, you can shift to a predictive approach.

Example: Wireless vibration and temperature sensors mounted on critical motors can detect early signs of wear, imbalance, or overheating. This allows maintenance teams to act before a breakdown occurs—reducing unplanned downtime and extending asset life.

Asset Tracking & Operational Visibility

Factories often struggle with limited visibility into machine performance, especially across large or distributed facilities. IoT sensors provide in-time data on key parameters like equipment status, cycle times, and material flows.

Example: A wireless sensor network installed across different production lines can feed data into a central dashboard—helping managers instantly identify bottlenecks or idle assets and respond accordingly.

Energy Efficiency and Cost Reduction

Energy is one of the largest operating costs in manufacturing. IIoT systems can help track power consumption at the device level, allowing factories to identify inefficiencies and optimize energy use.

Example: By deploying wireless power meters or current sensors, a plant can detect when a machine is consuming power even during idle periods—and automatically trigger shutdowns or alerts.

How to Apply Wireless Sensors in Key Factory Scenarios?

Adopting Industrial IoT often begins with a simple question: Where should we start? For many factory operations managers, the challenge isn’t whether IIoT is valuable—it’s knowing which use cases to prioritize and how to deploy sensors effectively without disrupting existing systems. This section outlines four practical factory scenarios where wireless sensors can deliver immediate value. Each scenario includes:

A common operational challenge

The right type of sensor to address it

A suggested installation approach using Daviteq’s wireless devices

Whether you're aiming to reduce unplanned downtime, optimize energy usage, or gain better visibility into your processes, these examples can help you build momentum for your IIoT journey—one sensor at a time.

Smart Manufacturing with Condition Monitoring

One of the most common—and high-impact—starting points for wireless sensor deployment is monitoring the condition of rotating equipment such as motors, compressors, and pumps. These machines are critical to production but prone to failure due to overload, wear, or no-load operation. By tracking electrical load patterns, you can gain early insight into equipment health, prevent downtime, and improve maintenance scheduling—all without interfering with control systems or rewiring your plant.

Installation suggestion: Start by identifying your most critical equipment: motors driving conveyors, compressors, or mixers. Install Daviteq’s WSLRW-AC – LoRaWAN AC Current Sensor on the power lines using split-core current transformers (CTs) with 5A output. The sensor can monitor:

Current load (A) of each machine

Energy usage over time

No-load or overload conditions

Runtime hours

Thanks to its wireless LoRaWAN communication and 10-year battery life, the WSLRW-AC can be deployed without rewiring. Data is sent every few minutes to a local LoRaWAN gateway, and from there to your cloud platform, SCADA, or analytics dashboard. This setup allows your team to move from reactive maintenance to data-driven decision-making, helping maximize uptime and resource efficiency.

Remote Equipment Monitoring in Harsh Environments

Industrial sites often include hard-to-reach or hazardous areas—such as boiler rooms, pressurized pipelines, or sealed processing vessels—where wiring is impractical and manual inspections are costly or unsafe. Deploying wireless sensors in these zones enables continuous monitoring without exposing personnel or interrupting operations.

Installation suggestion: Identify high-risk locations such as:

Steam pipes and vessels

Pressurized chemical tanks

Outdoor or underground pumping stations

Install Daviteq’s WSLRW-PPS – LoRaWAN Process Pressure Sensor directly onto pressure ports or threaded inlets using the appropriate gauge type (Gauge, Absolute, or Sealed). The sensor supports a wide range of pressures (1 to 1000 bar) and is IP68-rated, suitable for both indoor and outdoor deployment. Powered by two AA batteries, the sensor can operate for up to 10 years and wirelessly transmit pressure data over several kilometers to a LoRaWAN gateway, even in areas with limited network infrastructure.

This setup enables your team to:

Detect pressure anomalies (drops, spikes, loss of containment)

Reduce manual inspections in confined or hazardous spaces

Improve safety while ensuring system uptime and compliance

Digital Twin & Process Optimization

Creating a digital twin of your production process requires real-world data—accurate, continuous, and wireless. Whether you’re optimizing a mixing cycle, managing tank levels, or simulating batch performance, sensor-driven visibility is the foundation.

Installation suggestion: Identify liquid tanks, storage silos, or mixing vessels that play a central role in your process. Install Daviteq’s WSLRW-RLC – LoRaWAN Miniature Radar Level Sensor on the top flange or opening of the tank. This sensor uses 60GHz pulse radar technology to measure liquid levels with high precision, even in harsh or narrow environments. Powered by 2 x AA batteries, the sensor operates up to 10 years and transmits data wirelessly to a LoRaWAN gateway. It’s rated IP67, ideal for both indoor and outdoor use.

Recommended use cases include:

Monitoring raw material levels in real time

Tracking consumption for inventory control

Simulating tank behavior in digital twin models

Triggering refills or alerts based on live level thresholds

Once integrated into your SCADA or digital twin platform, the data can be used to optimize batch timing, reduce downtime, and support predictive control logic—all without manual measurement or sensor wiring.

Cold Chain Monitoring in Industrial Warehouses

Cold storage environments demand precise control of temperature and humidity to prevent spoilage and maintain compliance—especially for pharmaceuticals, chemicals, and perishable goods.

Manual checks or wired systems are often impractical in walk-in freezers, cold rooms, or mobile containers. That’s where wireless sensors offer a scalable, maintenance-free solution.

Installation suggestion: Deploy Daviteq’s WSLRW-ATH – LoRaWAN Humidity & Temperature Sensor across your cold storage zones, racks, or cooling units. Use the remote probe version to place the sensor tip directly inside freezers, while keeping the wireless body outside the sealed environment.

Each sensor captures:

Ambient temperature (°C)

Relative humidity (%)

Set reporting intervals every 5–10 minutes. Data is transmitted via LoRaWAN to a central gateway and dashboard where alerts can be configured for threshold breaches or power loss events. Ideal applications include:

Cold storage warehouses for pharmaceuticals or food

Temperature-controlled production zones

Monitoring vaccine transport containers

Regulatory audit compliance (GxP, HACCP)

With up to 10 years of battery life and minimal maintenance, WSLRW-ATH provides a reliable, scalable foundation for end-to-end cold chain visibility.

Challenges to Consider

While the benefits of IoT-powered automation are compelling, successful implementation isn’t without its challenges. Understanding these hurdles early on can help you plan more effectively and avoid costly missteps.

System Integration with Legacy Infrastructure

One of the most common barriers to IIoT adoption in factories is the presence of legacy control systems—PLCs, SCADA platforms, or industrial networks that were never designed with IoT connectivity in mind. These systems often use proprietary protocols, lack modern data interfaces, and may not be well-documented, making integration a technical challenge. Without a clear integration plan, manufacturers risk facing compatibility issues, data silos, and a longer time to ROI.

Data Accuracy and Calibration

In an IIoT system, poor data is worse than no data. If sensor readings are inaccurate, inconsistent, or affected by environmental interference, they can mislead operators and trigger incorrect decisions—compromising both efficiency and safety.

Wireless sensors are especially sensitive to installation quality and calibration. A small mounting error or skipped calibration step can create long-term drift or noise in your analytics platform, undermining trust in the system.

Network Reliability and Coverage

Even the most advanced wireless sensors are only useful if their data consistently reaches the gateway. In industrial environments—where thick concrete walls, metal structures, and electromagnetic noise are common—radio signal propagation can be unpredictable.

LoRaWAN and other LPWAN technologies offer long-range communication, but signal degradation, packet loss, or blind spots can occur without proper planning. These gaps in data transmission may go unnoticed until they cause operational blind spots or loss of critical alerts.

Data Security and Access Control

Introducing wireless connectivity into industrial systems can open new cybersecurity risks. Unlike closed-loop PLC networks, IIoT solutions often involve cloud transmission, remote dashboards, or over-the-air configuration—all of which expand the attack surface.

If not properly secured, sensors and gateways could become entry points for unauthorized access, data leaks, or even malicious control signals. For industries subject to strict compliance (e.g., pharmaceuticals, energy), data integrity and access control are non-negotiable.

Change Management and User Adoption

IIoT transformation isn’t just about deploying new devices—it’s about changing how people work with data. Even the most advanced wireless sensor system can fail to deliver value if operators don’t trust the data, maintenance teams aren’t trained to act on alerts, or managers don’t see how it fits their goals.

Resistance to change, lack of digital skills, or “pilot purgatory” (never moving beyond testing) are common pitfalls in industrial settings.

How to Get Started with IoT in Your Factory

Getting started with Industrial IoT doesn’t mean overhauling your entire production line overnight. In fact, the most successful factories begin with a few focused steps that align with their real operational challenges. Here's how to approach it.

The first step is to assess your current operations. Walk through your shop floor and identify where inefficiencies or blind spots exist. Are there machines that still require manual logging? Do your teams spend time collecting data that could be automated? Are you often reacting to failures instead of anticipating them? This situational awareness helps pinpoint the areas where IoT could bring the most impact.

Next, it's important to define clear business goals before choosing any technology. Rather than “digitizing for the sake of it,” think about what outcomes you want to achieve. It could be reducing unexpected downtime, improving energy efficiency, or streamlining compliance reporting in temperature-controlled zones. Setting measurable KPIs will help build alignment between operations, maintenance, and management.

Once goals are clear, move on to launching a pilot project. You don’t need to instrument the whole factory from day one. Choose one process, machine group, or area where the impact is easy to measure and visible to key stakeholders. For example, deploying wireless current sensors to monitor pump motors or placing humidity and temperature sensors in a cold room. The pilot is where you test the hardware, verify network reliability, and validate whether the collected data is truly useful for decision-making.

After a successful pilot, it’s time to select the right hardware and platform to support scaling. This includes choosing wireless sensors with long battery life, gateways that support industrial protocols like Modbus or MQTT, and a data platform—either cloud or on-prem—that integrates well with your existing systems. Don’t overlook vendor support; having a local or responsive partner can dramatically simplify deployment.

Finally, use what you’ve learned to scale based on real insights. Expand your deployment gradually across similar assets or process lines. Let the data guide you—identify trends, fine-tune alert thresholds, and improve your preventive maintenance planning. The key is not to aim for perfection from the beginning, but to build confidence across teams and systems, step by step.

Industrial automation is no longer just about PLCs and control logic—it’s about harnessing in-time data from the field to make smarter, faster decisions. With wireless sensors, manufacturers like you can unlock insights from assets that were once invisible, automate what used to be manual, and respond with agility in a competitive market.

The key is not to wait for the perfect system or the biggest budget. Instead, start with one area that matters, one metric you want to improve, and build momentum from there. With scalable solutions like LoRaWAN sensors, open protocols, and hybrid integration strategies, IoT is now more accessible than ever.

Comments