How M2M Communication Empowers Smart Industry

- Nguyen Vinh Loc

- Aug 7, 2025

- 10 min read

Updated: Aug 15, 2025

As machines become more intelligent and connected, the way they interact is transforming how industries operate. From autonomous equipment in factories to self-triggered irrigation in agriculture and responsive infrastructure in smart cities, one technology enables it all: Machine-to-Machine (M2M) communication.

In essence, M2M communication in IoT refers to the seamless exchange of data between devices—without human involvement. This foundational technology is quietly powering the automation revolution, enabling machines to monitor, decide, and act on their own. Whether it’s a vibration sensor halting a failing motor, a soil sensor activating a water valve, or a level sensor sending an overflow alert, M2M makes it possible in real time, reliably, and often without needing internet access.

At Daviteq, we build wireless sensor systems that bring machine-to-machine M2M communications in IoT to life—across factories, farms, and cities. In this blog, we’ll break down:

What is M2M in IoT and how it works

The difference between M2M and IoT

Real-world applications in manufacturing, agriculture, and public services

Key considerations, benefits, and challenges of deploying M2M

And how Daviteq’s sensors empower smarter, faster, and more autonomous operations

Whether you're managing an industrial plant, growing crops in a remote field, or overseeing urban infrastructure, understanding M2M technology in IoT is your first step toward automation that works—machine to machine.

What Is M2M Communication in IoT and Why It Matters?

M2M, or Machine-to-Machine communication, is the ability of machines, sensors, and controllers to exchange data and take action—without the need for human input. In an industrial context, that might mean a vibration sensor detects abnormal resonance in a motor and automatically tells a control unit to shut it down. In agriculture, a soil moisture sensor could trigger irrigation the moment a dry threshold is crossed. In both cases, M2M enables machines to “talk” and “act” directly, in real time.

So, what is M2M in IoT, and how does it fit in? While M2M communication predates the Internet of Things, it has become a core component of IoT systems. M2M communication in IoT refers specifically to automated, device-to-device messaging within a broader connected ecosystem. It provides the low-latency, high-reliability layer needed for real-time actions—often at the edge of the network.

Unlike traditional systems that require human supervision or cloud-based processing, machine to machine (M2M) communications in IoT are typically:

Autonomous: Devices exchange data and trigger actions based on predefined logic

Localized: Many M2M interactions occur at the edge—reducing dependence on internet connectivity

Deterministic: Timing and reliability matter, especially in industrial control or utility systems

Understanding the meaning of M2M in IoT is essential because it defines how future-ready your operations can be. M2M allows businesses to:

Automate critical processes without cloud latency

Respond instantly to changes in the physical world

Reduce human error, increase uptime, and lower operating costs

In short, M2M isn’t just a buzzword—it’s the invisible network behind smarter machines, smarter responses, and smarter decisions.

How M2M Communication Works in Wireless Sensor Systems

At its core, M2M technology in IoT enables physical devices—like sensors, controllers, and actuators—to communicate directly through a network, enabling fast, autonomous reactions to changing conditions. In wireless sensor systems, M2M plays a central role by eliminating the need for hard-wired control logic or human-triggered decisions.

A typical wireless M2M architecture includes the following layers:

End Devices (Sensors & Actuators): Devices like vibration sensors, temperature probes, or soil moisture sensors gather environmental or machine data. Actuators (such as valves or relays) execute preprogrammed actions based on sensor input.

Communication Network: Devices communicate via wireless protocols such as LoRaWAN, Sigfox, NB-IoT, or LTE-M. These LPWAN technologies are ideal for long-range, low-power M2M communication in industrial, agricultural, or urban settings.

Gateway or Edge Controller: Gateways receive data from devices and either forward it to the cloud (in IoT systems) or make decisions locally in M2M systems. For example, Daviteq’s Globiots Gateway can be configured to react instantly to sensor inputs—without cloud reliance.

Backend or Platform (optional): For extended logic, reporting, or cloud analytics, data may be sent to SCADA, ERP, or an IoT platform. However, in many M2M deployments—especially in remote farms or industrial automation—the system works independently of the cloud.

This architecture allows M2M systems to execute in-time responses to local events, such as shutting down equipment during vibration spikes or irrigating crops based on moisture thresholds—all without waiting for centralized input.

Types of M2M Communication

M2M isn’t a one-size-fits-all model. Depending on the deployment environment, communication range, and connectivity needs, several types of M2M communication are used:

Cellular-based M2M: Uses 4G/5G or LTE-M networks. Ideal for mobile or wide-area deployments (e.g., vehicle fleets, utility metering).

Satellite-based M2M: Offers coverage in remote areas with no terrestrial network—suitable for offshore, agriculture, or mining use cases.

RFID-based M2M: Combines sensors with RFID tags/readers for short-range asset tracking (e.g., inventory or livestock).

Industrial M2M: Built for rugged, high-performance environments, often using proprietary protocols or industrial buses like Modbus/RS485 alongside wireless overlays.

In wireless sensor deployments, choosing the right combination of these M2M types is essential to ensuring low power consumption, reliable communication, and actionable automation. Daviteq’s wireless sensors are designed to support multiple M2M models, making them suitable for both cloud-connected IoT and standalone M2M operations at the edge.

M2M vs IoT: What’s the Difference and Why It Matters

While M2M and IoT are often used interchangeably, they are not the same. Understanding the difference between the two is essential when designing connected systems—especially in industrial or mission-critical environments.

At its core, M2M in IoT refers to direct, point-to-point communication between devices. These systems are often deployed for very specific, isolated functions—like shutting off a pump based on pressure readings or triggering a light alert when a machine vibrates abnormally.

On the other hand, IoT (Internet of Things) describes a broader, more integrated ecosystem where devices not only talk to each other but also connect to cloud platforms, enabling centralized analytics, user interaction, AI models, and cross-device coordination.

Here’s a breakdown of how they compare:

Aspect | M2M | IoT |

Architecture | Point-to-point (device ↔ device) | Cloud-centric (device → cloud → other devices) |

Scope | Narrow-purpose | Multi-purpose, system-wide |

Cloud Dependency | Often operates without cloud | Typically requires cloud |

Communication | Cellular, LPWAN, wired | Internet-based (IP), protocols like MQTT, CoAP |

Flexibility | Fixed logic, hard-coded | Dynamic, scalable, updatable |

Use Case | Local automation, control systems | Predictive analytics, dashboards, mobile apps |

In many industrial and agricultural environments, M2M technology in IoT is the best starting point. It offers real-time responsiveness, low bandwidth usage, and the ability to operate without full-time internet access. That’s why M2M is still widely used in smart factories, farms, and city infrastructure where reliability and determinism matter more than cloud analytics.

That said, M2M and IoT are not mutually exclusive. The most resilient systems combine both:

M2M for immediate, autonomous control at the edge

IoT for centralized monitoring, insights, and optimization over time

Daviteq’s wireless sensor ecosystem supports both M2M-style local control and cloud-based IoT integration, giving you full flexibility to start simple—and scale smart.

Real-World Applications of M2M Across Industries

When it comes to real-world performance, M2M technology in IoT shines brightest in environments where speed, autonomy, and reliability matter most. Below are three powerful examples of how wireless M2M communication enables smarter operations across industries—with the help of Daviteq’s industrial-grade sensors.

Smart Factory: Proactive Maintenance and Autonomous Control

In industrial settings, unplanned downtime is more than an inconvenience—it’s a direct hit to productivity, revenue, and safety. Traditional maintenance models often rely on scheduled inspections or human reporting, which can be slow and reactive. That’s where machine-to-machine (M2M) communication in industrial automation changes the game.

Let’s take the example of a production line motor. By installing a WS433-V1A wireless vibration sensor on the motor housing, the system continuously monitors vibration levels. When the sensor detects signs of imbalance, bearing failure, or mechanical looseness, it sends an immediate M2M signal—via Sub-GHz wireless—to a local controller or gateway.

This signal automatically triggers an action, such as:

Shutting down the equipment

Activating a local alarm

Logging the anomaly for root-cause analysis

All of this happens without cloud dependency, without internet access, and without human delay—thanks to M2M technology in IoT that enables devices to communicate autonomously at the edge.

Smart Agriculture: Automated Irrigation and Weather-Based Decisions

For farmers managing large or remote fields, manually controlling irrigation can be time-consuming, inconsistent, and heavily dependent on weather guesswork. This challenge becomes even more pressing in regions with limited internet access or labor shortages.

With M2M communication in agriculture, these limitations disappear. Take the example of a LoRaWAN soil moisture sensor like Daviteq’s WSLRW-SMT. Once installed in the field, the sensor constantly measures real-time soil moisture levels at the root zone. When dryness crosses a predefined threshold, it sends a direct wireless signal to activate a local irrigation valve—no human, no cloud, no delay.

This local machine-to-machine trigger ensures crops get the right amount of water exactly when they need it—regardless of connectivity or external commands. The system can even be configured to respond to combined signals from humidity, temperature, or rainfall sensors, forming a fully autonomous, weather-aware irrigation logic.

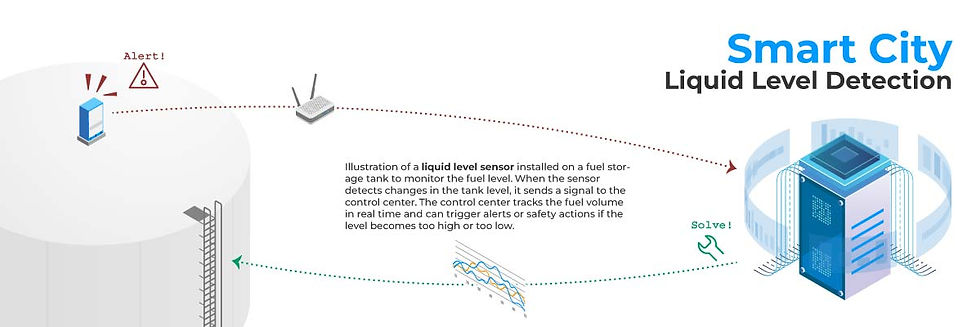

Smart City & Utilities: Monitoring and Triggering Critical Operations

Cities today face mounting pressure to deliver timely, reliable services—whether it’s emptying full waste bins, managing stormwater levels, or detecting overflow in water tanks. Relying on manual inspections or fixed schedules often results in delays, inefficiencies, or even hazards.

With machine-to-machine communication, these operations can run smarter and faster. For example, the WSLRW-ULC LoRaWAN Ultrasonic Level Sensor continuously monitors the liquid level in tanks, reservoirs, or sewage systems. When the level crosses a predefined threshold, it sends a direct M2M signal to trigger an action—such as opening a drain valve, sending an alert, or activating a pump.

Because the sensor operates via LoRaWAN and includes long-range transmission plus a 10-year battery, it’s ideal for remote or hard-to-access locations—all without depending on cloud connectivity or manual checks.

Benefits of M2M in Industrial and Urban Systems

The value of machine-to-machine (M2M) communication extends far beyond individual device interactions—it redefines how entire systems operate. In both industrial and urban contexts, M2M brings tangible benefits by enabling real-time decision-making directly at the edge, without relying on cloud connectivity. This makes it ideal for time-sensitive processes like shutting down malfunctioning equipment, activating irrigation in dry soil, or triggering flood responses in storm drains.

One of the most immediate advantages is cost reduction. By automating local responses and minimizing human intervention, M2M reduces labor expenses, energy usage, and unnecessary equipment wear. It also supports predictive maintenance, helping businesses prevent downtime and extend asset lifespan.

Crucially, M2M systems are well-suited to offline or remote environments. Farms with limited internet access or underground utility infrastructure can still operate intelligently thanks to localized, peer-to-peer communication. Additionally, M2M is highly scalable and retrofit-friendly—you can start small and expand gradually without needing to overhaul legacy systems.

Finally, while M2M functions independently, it also integrates smoothly with cloud-based IoT platforms. This means businesses can act instantly at the edge and still collect data for analytics, reporting, or optimization over time. In short, M2M offers the perfect balance between autonomy and insight—delivering fast, reliable, and cost-effective automation for the real world.

Key Considerations for Implementing M2M Solutions

While the benefits of machine-to-machine communication are clear, successful deployment depends on careful planning and the right technological choices. M2M systems are often installed in critical environments—factories, farms, city infrastructure—so reliability, scalability, and security are essential from day one.

First, it’s important to choose the right communication protocol for your use case. LPWAN options like LoRaWAN, Sigfox, and NB-IoT are ideal for long-range, low-power applications in agriculture and smart cities. In industrial settings, Sub-GHz protocols (like 433MHz) offer ultra-stable connections for high-interference environments. Cellular (4G/5G) or Ethernet may also be required for bandwidth-intensive M2M tasks.

Next, consider device management and configuration. M2M deployments often span hundreds or thousands of sensors—so the ability to remotely configure devices (OTA) and update firmware over the air is a must. Solutions like Daviteq’s Globiots platform offer centralized tools for managing devices, data rates, alert thresholds, and battery status from anywhere.

Security cannot be overlooked. Because M2M systems operate autonomously and sometimes in remote or unmanned areas, they must be protected against unauthorized access, spoofing, or data leaks. Standards like OMA Lightweight M2M (LwM2M), MQTT with TLS, and TR-069 provide encryption, authentication, and remote device management protocols tailored for M2M applications.

From a system design perspective, following ETSI’s M2M requirements is essential to ensure performance at scale. These include:

Scalability to handle thousands of nodes

Efficient message delivery, including support for broadcast, unicast, or peer-to-peer communication

Transmission scheduling to control message timing and reduce network congestion

Communication path optimization to reroute around failed links or reduce latency

Ultimately, deploying M2M successfully is not just about connecting devices—it’s about creating an autonomous system that can monitor, decide, and act with minimal human input, even under harsh conditions. By prioritizing protocol compatibility, device manageability, and security from the start, organizations can build robust, future-ready M2M solutions tailored to their operational needs.

The Future of M2M: AI, 5G and Edge Computing

As industries demand faster, smarter, and more autonomous systems, Machine-to-Machine (M2M) communication is evolving beyond simple device-to-device interactions. The future of M2M lies at the intersection of artificial intelligence (AI), 5G networks, and edge computing—technologies that dramatically enhance how machines think, talk, and act.

AI: Turning M2M into Intelligent Decision-Making

Today’s M2M systems are rule-based—they follow predefined logic. But with AI, machines can go further. By embedding machine learning algorithms at the edge, M2M devices can analyze trends, learn from anomalies, and make dynamic decisions. For example, a vibration sensor might not just detect excess movement—it could predict mechanical failure patterns before they happen.

5G: Unlocking High-Speed, Ultra-Reliable M2M

The rollout of 5G networks enables M2M communication at massive scale and near-zero latency. With ultra-reliable low-latency communication (URLLC), M2M systems in automotive, robotics, or public safety can operate in real time—even in motion. This opens doors to vehicle-to-vehicle (V2V) M2M, drone coordination, and smart traffic systems.

Edge Computing: Autonomous Systems Without the Cloud

The future of M2M is also increasingly cloud-optional. Thanks to powerful edge gateways, more processing is happening closer to the data source. This reduces latency, lowers bandwidth costs, and improves reliability in areas with poor connectivity. With edge AI + M2M, machines can sense, analyze, and act—all within milliseconds—without depending on internet or cloud availability.

In short, the future of M2M is not just about connectivity—it’s about intelligence. With AI, 5G, and edge processing working together, tomorrow’s machines won’t just respond—they’ll anticipate, adapt, and optimize their environment in ways that were once impossible.

In an increasingly automated and data-driven world, Machine-to-Machine (M2M) communication has become a foundational technology—bridging the gap between sensors, devices, and intelligent actions. From real-time vibration alerts on factory floors to autonomous irrigation in remote farms, or level monitoring in city infrastructure, M2M empowers systems to operate smarter, faster, and more independently.

Unlike traditional architectures that rely heavily on cloud or manual oversight, M2M allows decisions to be made at the edge—where speed, reliability, and autonomy are most critical. And as AI, 5G, and edge computing mature, M2M will continue to evolve from simple triggers to intelligent, adaptive systems across industries.

At Daviteq, we’ve built a wireless sensor ecosystem designed specifically for this future—scalable, low-power, and compatible with LoRaWAN, Sub-GHz, NB-IoT, and more. Whether you’re digitizing a smart factory, optimizing farm irrigation, or modernizing city services, M2M isn’t just a technology—it’s your automation backbone.

Comments